High-density polyethylene is one of the materials used to make heavy-duty liners and geomembranes. HDPE is the thickest liner, with thickness ranging from 20 mils to 120 mils. BPM Geomembrane is a company specializing in the production of geomembranes. With a professional production and R&D team, it can produce geomembranes of various specifications and sizes.Let’s discuss the characteristics and applications of 40 mil HDPE Liner.

1. What Is 40 Mil HDPE Liner?

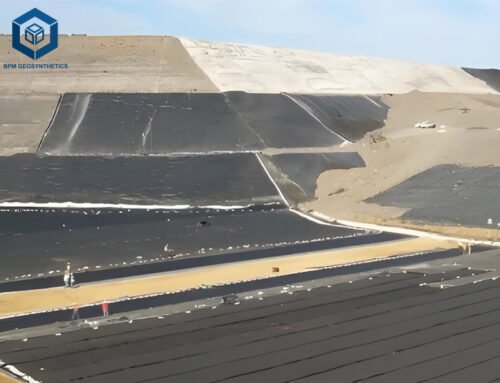

The 40 Mil HDPE Liner, a waterproof barrier material made from high molecular polymers, primarily functions by leveraging the impermeability of plastic film to obstruct leakage pathways in earthen dams. It utilizes its substantial tensile strength and elongation to endure water pressure and accommodate the deformations of the dam body. This liner exhibits excellent resistance to bacterial corrosion and chemical reactions, showing no signs of degradation when exposed to acids, alkalis, or salts. When shielded from light, it boasts an extended service life.

2. What Are Benefits of 40 Mil HDPE Liner?

A 40 mil HDPE liner offers several benefits due to its specific characteristics and thickness. Some advantages of using a 40 mil HDPE liner include:

2.1 Thickness:

The 40 mil thickness provides enhanced durability and puncture resistance, making it suitable for applications requiring robust containment solutions.

2.2 Chemical Resistance:

HDPE liners are known for their excellent resistance to a wide range of chemicals, making them ideal for applications where exposure to hazardous substances is a concern.

2.3 UV Resistance:

HDPE liners are UV stabilized, offering protection against degradation due to prolonged exposure to sunlight, ensuring long-term performance in outdoor applications.

2.4 Flexibility:

Despite its thickness, a 40 mil HDPE liner remains flexible, allowing it to conform to the shape of the underlying surface and accommodate ground movement without compromising its integrity.

2.5 Impermeability:

HDPE liners exhibit high impermeability, preventing the passage of liquids and gases, which is crucial in containment applications such as landfill liners, pond liners, and tank linings.

2.6 Ease of Installation:

HDPE liners are typically easy to install, reducing labor costs and installation time compared to other lining materials.

2.7 Longevity:

The durability and resistance to environmental factors of a 40 mil HDPE liner contribute to its longevity, providing a reliable containment solution for long-term use.

3. What Are Applications Of 40 Mil HDPE Liner?

A 40 mil high-density polyethylene (HDPE) liner, with its specific thickness and properties, finds applications in various industries and projects where containment, protection, and impermeability are crucial.

3.1 Landfills:

Used as liners in landfills to prevent leachate from contaminating soil and groundwater, ensuring environmental protection.

3.2 Pond and Reservoir Liners:

Installed in ponds, reservoirs, and water storage facilities to create impermeable barriers, preventing water seepage and facilitating water containment.

3.3 Mining Operations:

Applied in mining operations for containment purposes, such as lining tailings ponds, heap leach pads, and storage facilities for industrial waste materials.

3.4 Wastewater Treatment:

Utilized in wastewater treatment plants to line lagoons, tanks, and other structures, preventing the infiltration of contaminants into the environment.

3.5 Agricultural Applications:

Used in agriculture for lining irrigation ponds, manure storage facilities, and other containment structures to prevent seepage and protect soil and water quality.

3.6 Secondary Containment:

Employed in secondary containment systems to store hazardous materials, chemicals, or fuel, providing an additional layer of protection against leaks and spills.

3.7 Industrial Applications:

Used in industrial facilities for containment purposes, such as lining storage tanks, chemical containment areas, and other structures requiring impermeable barriers.

3.8 Aquaculture:

Applied in aquaculture settings for lining fish ponds, hatcheries, and other aquatic containment systems to prevent water seepage and maintain optimal conditions.

4. How To Choose Right 40 Mil HDPE Liner?

4.1 Application:

Determine the specific use case to ensure the liner meets necessary requirements for chemical resistance, UV protection, and durability.

4.2 Material Quality:

Look for high-quality HDPE materials that are certified for environmental applications.

4.3 Manufacturer Reputation:

Choose a reputable manufacturer known for producing consistent, high-quality liners.

4.4 UV Protection:

Ensure the liner has UV stabilizers if it will be exposed to sunlight.

4.5 Installation Method:

Consider the installation method and choose a liner that can be easily and securely seamed or welded.

4.6 Thickness and Durability:

While all are 40 mils thick, check the material’s density and tensile strength to ensure it can withstand the anticipated loads and stresses.

4.7 Regulatory Compliance:

Ensure the liner meets local, state, and federal regulations for the intended application.

4.8 Cost:

Evaluate the cost against the expected performance and longevity of the liner.

4.9 Warranty and Support:

Consider the manufacturer’s warranty and technical support offerings.

4.10 Geometry and Size:

Ensure the liner can be custom-fitted to the project’s specific dimensions and shape.

BPM Geomembrane has 14 years of experience in geomembrane production, and the 40 Mil HDPE Liner produced by it far exceeds the ASTM GM13 standard. At the same time, it also has a professional installation and after-sales team, so you can purchase without worries.

5. How To Install 40 Mil HDPE Liner?

Installing a 40 mil HDPE liner requires careful planning and execution to ensure proper containment and longevity.

5.1 Ground Preparation:

Ensure the installation area is clean, flat, and compacted. Remove any sharp objects or debris that could puncture the liner.

5.2 Measurement and Cutting:

Measure the area to be covered and add an extra 5-10% for overlapping and settlement. Cut the liner to the required size using a sharp knife or a straight edge and marking tool.

5.3 Seaming:

If the project requires multiple sheets of liner, seam them together using a thermal welding process. This involves melting the two edges of the liner together to form a watertight seal.

5.4 Laying Out the Liner:

Roll out the liner onto the prepared surface, taking care not to stretch or damage it. Use stakes or sandbags to secure the edges temporarily.

5.5 Adjustments and Alignment:

Smooth out any wrinkles and ensure the liner is correctly aligned, leaving enough space for final anchoring.

5.6 Anchoring:

Secure the edges of the liner with soil, rocks, or other materials to prevent it from moving or being lifted by fluid pressure.

5.7 Leak Testing:

Once the liner is in place, perform a leak test to ensure there are no pinholes or seam failures. This can be done by filling the lined area with water and monitoring for any leakage.

5.8 Final Inspection:

Carefully inspect the entire liner for any signs of damage or incorrect installation. Address any issues before proceeding with the next phase of construction or use.

6. Summary

As a superior waterproof geotechnical material, the 40 Mil HDPE Liner is extensively utilized and is frequently paired with geotextiles to enhance project outcomes. Selecting the appropriate 40 Mil HDPE Liner is crucial. BPM Geosynthetics’ 40 Mil HDPE Liner is manufactured using 100% virgin materials and equipment of international superior standards, ensuring its product quality greatly surpasses international benchmarks.

If you have any further questions, please feel free to contact us.