Selecting the best HDPE Liner is critical to the success and durability of an engineering project. This comprehensive guide provides valuable insights into the process of making the best selection. It covers the fundamentals of HDPE Liners, considers engineering requirements, and explores factors such as waterproofing, corrosion resistance, and ageing resistance. The guide highlights the reputation of manufacturers, material testing,hdpe liner cost and quality assurance systems, underscoring the importance of reliability and consistency.

BPM Geomembrane HDPE Liners addresses issues of ease of installation, maintenance costs, and environmental impact, enabling decision makers to prioritize project quality and sustainability. This guide provides practical advice and expert insights, making it an indispensable resource for elevating civil engineering practices in world.

1. What is HDPE Liner?

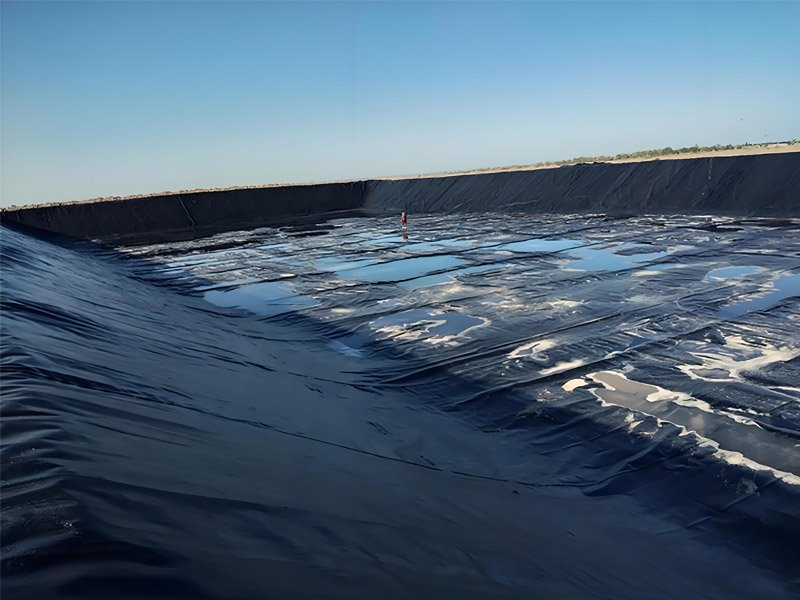

HDPE Liners, also known as HDPE Liners, are widely used waterproofing materials in civil engineering projects. They are synthetic materials used for containment, lining, and barrier purposes in a variety of civil and environmental engineering applications. The main function of these HDPE Liners is to form an impermeable barrier that prevents the migration of fluids and gases, ensures environmental protection, and maintains the integrity of engineering structures.

They are durable, flexible, chemically resistant and able to withstand harsh environmental conditions, including UV radiation, temperature fluctuations and chemical exposure.

In modern civil engineering practice, HDPE Liners play a key role in providing effective solutions to containment, environmental protection and resource management challenges. As technology advances and sustainability becomes increasingly important, HDPE Liners continue to evolve to provide innovative solutions for a wide range of engineering applications.

2. Understand The Basic Properties Of HDPE Liners

Before selecting a HDPE Liners, it is important to understand its basic properties. HDPE Liners mainly exhibit the following characteristics:

- Waterproof performance

- Corrosion resistance

- Ageing resistance

- Mechanical strength

With a clear understanding of these basic performance characteristics, engineers and project managers can make informed decisions when selecting the right HDPE Liners for their specific application. By carefully considering factors such as project requirements, site conditions and performance specifications, they can select the most appropriate HDPE Liners to ensure the success and durability of the engineering project.

3. Consider Engineering Requirements When Selecting HDPE Liners

When selecting HDPE Liners, actual engineering requirements must be considered. This includes the following aspects:

- Project environment

- Project specifications

- Project scale

Through a meticulous assessment of engineering requirements and careful consideration of the specific needs of the project, engineers and project managers can make wise choices when selecting HDPE Liners materials. These choices focus on meeting performance, durability and regulatory compliance requirements. By doing so, they ensure the successful implementation and long-term effectiveness of HDPE Liners-based engineering solutions.

4. What Are The Factors Affecting HDPE Liner Cost?

HDPE Liners are increasingly popular in many projects, such as fish ponds, dams, water treatment, landfills, mining, root barriers, biogas, etc. However, some clients may not understand the cost of HDPE Liners and may not know how to choose the appropriate HDPE Liners for their projects.

Our HDPE HDPE Liners is made of 100% native polyethylene resin and does not use any recycled waste materials. HDPE Liners have guaranteed performance and long service life.

The cost of HDPE Liners includes initial material cost, installation cost, maintenance cost, and service life cost.

4.1 HDPE Liner Cost – Initial material cost

The initial material cost mainly depends on the material quality. Some factories use secondary waste materials to make HDPE Liners. Although the material cost is very low, what do you think of the maintenance cost and lifespan cost.

Native PE HDPE Liners resin has high performance, and for large-scale civil engineering, water treatment, landfill sites, and mining engineering, HDPE Liners should have high technical data. The cost of HDPE Liners materials will increase, but the materials ensure the service life of these engineering projects. For example, our native HDPE HDPE Liners has a lifespan of 10-20 years for fish ponds and irrigation pools, and 40-60 years for landfill mining projects.

If you don’t know how to confirm the quality of materials and HDPE Liners, our engineers can help confirm and select the appropriate HDPE Liners.

4.2 HDPE Liner Cost – Installation and maintenance costs

The installation cost is affected by the quality of the HDPE Liners. If the quality of the original HDPE Liners is good, the welding machine efficiency is high, but the recycled material HDPE Liners will reduce the welding speed. The project requires more people and time to complete the installation. This will lead to an increase in the total cost of the project.

At the same time, once you choose recycled geosynthetic membranes, engineering failures will soon arrive, which will bring you maintenance trouble, waste time and money.

4.3 HDPE Liner Cost – Lifetime cost

The lifecycle cost is not significant, but it is sometimes overlooked.

The average lifespan should also be considered before placing an order. HDPE Liners with a successful performance record of over 30 years may have higher initial costs, but the return on investment will be higher than those with lower initial costs and can only be used for 5 to 15 years. Which one would you choose?

If you have a pond that requires the installation of HDPE Liners, please do not purchase any HDPE Liners before talking to our engineers, as they can help you find the materials suitable for your pond.

5. Consider HDPE Liners Installation And Maintenance

When choosing an HDPE Liner, factors related to installation and maintenance must also be considered. This includes the following aspects:

- Ease of installation

- Maintenance costs

- Environmental friendliness

Engineers and project managers can improve the performance, durability, and cost-effectiveness of HDPE Liners systems in various engineering applications by considering installation and maintenance factors.

By taking a proactive approach to installation and maintenance, they can reduce risks, extend the service life of HDPE Liners systems, and ultimately improve the overall success rate of projects. This comprehensive approach ensures optimal performance and maximizes the benefits of HDPE Liners in engineering projects.

6. Summary

In summary, choosing the right HDPE Liners material requires careful consideration of various factors. Understand HDPE Liners’ traits. Prioritize project needs and quality. Consider construction and maintenance. Pay attention to details for material choice. Adjust and optimize based on specific circumstances to ensure engineering safety and quality.

Please contact us for any questions or inquiries.

7. About BPM

BPM’s Tai’an plant, near Beijing-Shanghai highway in Shandong, China, has seen $20M+ investments in upgrades for facilities, wages, and technology. Our advanced HDPE liner production ensures top quality, swift delivery, and competitive costs for global clients. Products match or lead international standards, especially our smooth HDPE Liners. Customizable solutions include ODM, OEM. BPM Geosynthetics, a passionate 100+ professional team, specializes in HDPE Liners, nonwoven & woven variants, geonets, drainage composites, GCLs, and geogrids, offering comprehensive R&D, testing, manufacturing, and after-sales support worldwide.