Selecting the best geomembrane Australia is critical to the success and durability of an engineering project. This comprehensive guide provides valuable insights into the process of making the best selection. It covers the fundamentals of geomembranes, considers engineering requirements, and explores factors such as waterproofing, corrosion resistance, and ageing resistance. The guide highlights the reputation of manufacturers, material testing, and quality assurance systems, underscoring the importance of reliability and consistency.

BPM Geomembranes addresses issues of ease of installation, maintenance costs, and environmental impact, enabling decision makers to prioritize project quality and sustainability. This guide provides practical advice and expert insights, making it an indispensable resource for elevating civil engineering practices in Australia and beyond.

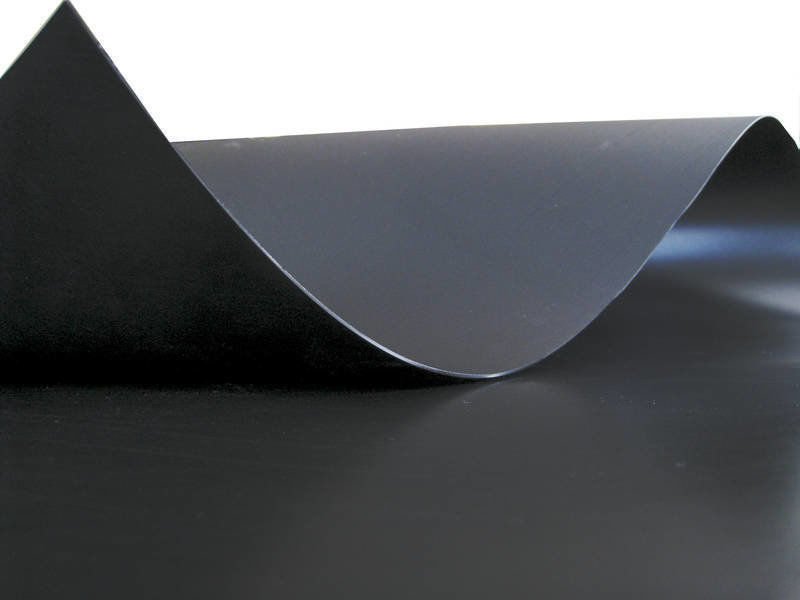

1. What Is Geomembrane Australia?

Geomembranes Australia, also known as Geomembrane Liners, are widely used waterproofing materials in civil engineering projects. They are synthetic materials used for containment, lining, and barrier purposes in a variety of civil and environmental engineering applications. The main function of these geomembranes is to form an impermeable barrier that prevents the migration of fluids and gases, ensures environmental protection, and maintains the integrity of engineering structures.

In modern civil engineering practice, geomembranes Australia play a key role in providing effective solutions to containment, environmental protection and resource management challenges. As technology advances and sustainability becomes increasingly important, geomembranes continue to evolve to provide innovative solutions for a wide range of engineering applications.

2. What Are Basic Properties of Geomembrane Australia?

Geomembranes used in Australia generally exhibit the following basic properties:

2.1 Thickness

Geomembranes in Australia are available in various thicknesses, typically ranging from 0.5 mm to 2.5 mm. The appropriate thickness depends on the specific application and engineering requirements.

2.2 Material Composition

Geomembranes used in Australia are commonly made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE). HDPE geomembranes are widely preferred due to their superior strength, durability, and chemical resistance.

2.3 Strength and Tear Resistance

Geomembranes in Australia possess high tensile strength to withstand stress and loads. They exhibit excellent tear resistance, which helps prevent damage during installation and operation.

2.4 Flexibility

Geomembranes are designed to be flexible and conform to irregular surfaces, ensuring proper coverage and containment. This flexibility allows them to adapt to ground movements and settlement.

2.5 Chemical Resistance

Geomembranes in Australia are resistant to a wide range of chemicals, including acids, alkalis, and organic solvents. This property ensures long-term stability and effectiveness in various environmental conditions.

2.6 UV Resistance

Geomembranes are formulated with UV stabilizers to withstand prolonged exposure to sunlight. This property prevents degradation and maintains the performance of the geomembrane over time.

2.7 Impermeability

Geomembranes serve as impermeable barriers, preventing the migration of liquids, gases, and contaminants. They provide effective containment and environmental protection in applications such as landfill liners, pond liners, and wastewater treatment facilities.

2.8 Weldability

Geomembranes in Australia are designed for efficient field seaming using thermal fusion welding techniques. The ability to create strong, reliable seams ensures the integrity of the liner system.

2.9 Longevity

Geomembranes are engineered for long-term performance and have a proven track record of durability and longevity in various applications. They can withstand harsh environmental conditions and maintain their effectiveness for extended periods.

3. How To Choosing Best Geomembrane Australia?

Choosing the best geomembrane in Australia involves considering several factors to ensure it meets the specific requirements of your project. Here are some key steps to help guide the selection process:

3.1 Identify Project Requirements

-

- Understand the purpose and scope of your project, including the type of containment or barrier system required.

- Determine the anticipated environmental conditions, such as temperature extremes, chemical exposure, UV exposure, and potential ground movement.

3.2 Assess Material Compatibility

-

- Evaluate the compatibility of the geomembrane with the substances it will come into contact with, such as chemicals, liquids, or waste materials.

- Consider the chemical resistance, permeability, and longevity of the geomembrane in relation to the specific project requirements.

3.3 Consider Installation Methods

-

- Determine the preferred installation method for the geomembrane, such as anchoring, welding, or seaming.

- Ensure that the selected geomembrane is compatible with the planned installation technique.

- Consider the expertise and availability of qualified installers experienced with the chosen geomembrane material.

3.4 Evaluate Strength and Durability

-

- Assess the required tensile strength, tear resistance, and puncture resistance of the geomembrane based on the project’s expected loads and potential risks.

- Consider the geomembrane’s ability to withstand ground movement, settlement, and other stress factors specific to the project site.

3.5 Verify Compliance with Standards and Regulations

-

- Check if there are any regulatory standards or guidelines specific to your project, such as those set by local authorities, environmental agencies, or industry associations.

- Ensure that the selected geomembrane complies with the relevant standards and regulations, providing necessary documentation and certifications as required.

3.6 Seek Expert Advice

-

- Consult with experienced geomembrane manufacturers, suppliers, or engineering consultants in Australia.

- Discuss your project requirements, site conditions, and specific challenges to gain insights and recommendations on the best geomembrane solution.

- Consider their expertise, track record, and reputation in the industry.

3.7 Compare Cost and Value

-

- Evaluate the cost-effectiveness of different geomembrane options.

- Consider the initial cost, installation expenses, long-term maintenance requirements, and expected lifespan of the geomembrane.

- Balance the upfront investment with the expected performance and durability to determine the best value for your project.

3.8 Request Samples and Test Data

-

- Request samples of the shortlisted geomembrane materials to examine their physical properties, texture, and thickness.

- Review test data or performance specifications provided by the manufacturers to verify the geomembrane’s suitability for your project requirements.

4. How To Maintain Geomembrane Australia?

Proper maintenance of geomembranes in Australia is essential to ensure their long-term performance and effectiveness. Here are some general guidelines for maintaining geomembranes:

4.1 Regular Inspection

-

- Conduct regular visual inspections of the geomembrane to identify any signs of damage, degradation, or wear.

- Inspect seams, welds, and connections for integrity and potential leaks.

- Look for signs of stress, punctures, tears, or other physical damage.

- Monitor the condition of any protective layers or covers placed over the geomembrane.

4.2 Cleaning and Debris Removal

-

- Remove debris, sediment, or vegetation that may accumulate on the geomembrane surface.

- Use non-abrasive cleaning methods, such as soft brushes or low-pressure water, to clean the geomembrane if necessary.

- Avoid using harsh chemicals or abrasive cleaning agents that may damage the geomembrane.

4.3 Repair and Maintenance

-

- Promptly address any identified damages or defects in the geomembrane.

- Repair punctures, tears, or damaged areas using appropriate repair techniques recommended by the manufacturer.

- Ensure that repairs are conducted by trained personnel following industry best practices.

- Regularly check and maintain any geotextile or protective layers associated with the geomembrane system.

4.4 Monitoring and Leak Detection

-

- Implement a monitoring system to detect leaks or seepage in the geomembrane.

- Use leak detection methods such as visual inspections, pressure testing, or electronic leak detection (ELD) technologies.

- Monitor groundwater levels, gas emissions, or liquid levels in containment systems to identify any potential leaks or breaches.

4.5 Preventive Measures

-

- Take preventive measures to minimize potential damage to the geomembrane.

- Implement erosion control measures to protect the geomembrane from excessive water flow or wave action.

- Ensure proper installation and anchoring of the geomembrane to prevent shifting or movement.

- Consider using protective layers, such as geotextiles or geosynthetic clay liners, to enhance the durability and performance of the geomembrane.

5. Summary

In summary, choosing the right geomembrane material requires comprehensive consideration of multiple factors. Understand the basic performance characteristics, engineering requirements and maintenance aspects of geomembranes. In practical applications, adjustments and optimizations should be made according to specific circumstances to ensure the overall quality and safety of the project.

If you have any questions or concerns, please contact us.