Textured HDPE liner, also known as textured geomembrane, is a type of High Density Polyethylene (HDPE) geomembrane that features a textured surface on one or both sides of the liner. This type of textured geomembrane is commonly utilized in mining operations and solid waste landfills. BPM is the HDPE geomembrane manufacturer and supplier, we offer various smooth and textured geomembrane at best price.

1. What Is Textured HDPE liner?

Textured HDPE liner is available with either single-side or double-side textured surfaces which exhibits superior shear strength and the highest multi-axial performance offered in the market. Textured HDPE liners, made from high-density polyethylene material, are commonly employed in mining operations and solid waste landfills due to their numerous advantages.

Compared with smooth geomembrane, the textured surface of these liners enhances friction angles, making them particularly beneficial for steep slope applications. By increasing friction, these liners improve stability by reducing slippage and offer greater void space capacity, enabling efficient containment of liquids and waste materials. Consequently, HDPE Textured geomembranes are an ideal choice for projects where slope stability and containment are critical.

HDPE geomembranes, including the textured variant, are synthetic liners widely used in environmental and civil engineering applications to control the movement of liquids, gases, and other substances. HDPE liners, known for their resistance to various solvents, are the most commonly used geomembrane liners globally. While HDPE is less flexible than LLDPE, it possesses higher specific strength and can withstand higher temperatures. Moreover, its exceptional chemical and ultraviolet resistance properties make it a highly cost-effective product.

Textured HDPE geomembranes offer reliable performance, durability, and cost-effectiveness in a wide range of applications requiring superior containment and stability.

BPM textured HDPE liner has a proven history of success in many lining applications for such projects which need increased friction between two layers and high steeper slopes as landfills, mining, retaining backfills and waste containment, etc.

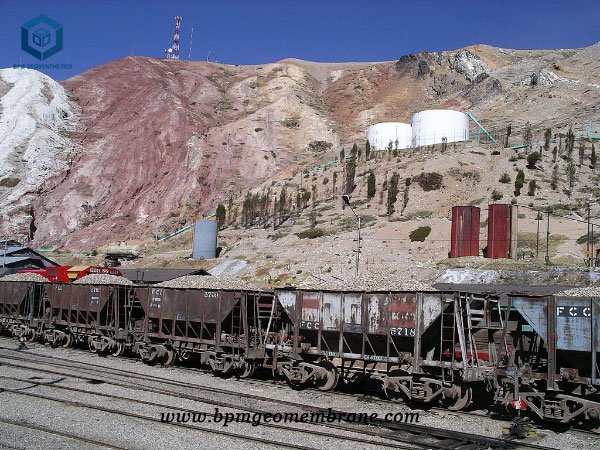

Mining is an important industry in Peru. In the recovery of metals by heap leaching, an impermeable base is required to minimize the risks of environmental contamination from leaching solutions, and to prevent seepage and loss of precious metal-rich solutions. A typical impermeable basal design will utilize a composite barrier system consisting of a textured HDPE liner overlying a compacted sub base.

The material considerations for geomembrane liners in heap leach pads include big friction angles, very low permeability, high chemical resistance, high temperature resistance, high tensile strength and elongation, high puncture resistance, high durability and high interface friction properties.

BPM offers two options for textured geomembranes: nitrogen induced and spray-on textured geomembrane. The measurement method used for these geomembranes is in accordance with the GRI-GM12 standard. Test properties and test frequency align with the specifications outlined in GRI-GM13. These standards ensure that BPM’s textured geomembranes meet the required quality and performance criteria. By adhering to these guidelines, BPM ensures that their geomembranes are reliable and suitable for various applications where textured surfaces are needed to enhance friction, stability, and containment.

BPM has manufactured and supplied high quality HDPE geomembrane liner for this industry for more than 10 years. BPM geomembranes include Smooth Geomembrane HDPE Liner, Textured HDPE Geomembrane, Composite Geomembrane Liner and geotextile membrane, etc. The smooth geomembrane HDPE Liner is available in three different colors such as black, white and green. The textured geomembrane can be fabricated with single or double-sided surface. Textured HDPE liner is the ideal geosynthetic product for mining projects with big slope. By working with experienced designers and operators, BPM has gathered a wealth of practical knowledge in the geoemembrane mining field. We understand the issues the HDPE geomembrane can solve. We are continously applying this knowledge to our textured HDPE liner design in pursuit of optimal containment solutions for heap leach mining.

2. What Are Benefits of Textured HDPE Liner?

BPM Textured HDPE Liners offer a range of benefits for various applications. Some key advantages include:

2.1 High interface friction values

The textured surface of the liner provides increased friction, making it ideal for steep slope designs. This helps improve stability and allows for higher landfill capacity.

2.2. Excellent resistance to hydrocarbons

The liner has exceptional resistance to hydrocarbons, making it suitable for secondary containment applications where protection against oil, fuel, and other hydrocarbon-based substances is crucial.

2.3 Excellent resistance to chemicals and industrial effluents

Textured HDPE Liners exhibit outstanding resistance to a wide range of chemicals and industrial effluents. This ensures reliable containment and protection against potential leaks or spills.

2.4 Outstanding environmental stress crack resistance and dimensional stability

The liner demonstrates excellent resistance to environmental stress cracking, maintaining its integrity and performance over time. It also exhibits dimensional stability, ensuring its effectiveness in various environmental conditions.

2.5 Thermal ageing characteristics

The liner retains its properties and performance even under high temperatures, making it suitable for applications where thermal stability is required.

2.6 Smooth salvaged edge option

The smooth salvaged edge option facilitates reliable seam welding and testing technology, ensuring secure and leak-proof seams in the liner.

BPM Textured HDPE Liners offer a combination of durability, chemical resistance, ease of installation, and enhanced friction properties, making them a reliable choice for applications such as landfill liners, secondary containment, and industrial storage facilities.

3. Why Chose Textured HDPE Liner Peru for Mining Project?

The textured HDPE liner from BPM was chosen for a mining project in Peru for several reasons. Firstly, the client had an opportunity to meet BPM at the Perumin exhibition in Arequipa, Peru, where they were impressed by the company’s professional knowledge and expertise in HDPE geomembrane and other geosynthetic products specifically designed for mining applications.

The client took some samples of the textured HDPE liner back to their office for evaluation. Upon reviewing the samples, they found that the liner met all the necessary requirements for their mining project. Additionally, the price offered by BPM was deemed suitable for their market.

Further communication with BPM’s engineers ensured that all the client’s specific project requirements were addressed. The client was satisfied with the responsiveness and support provided by BPM throughout the process.

Within a short timeframe of five days, BPM promptly arranged the shipment of the textured HDPE liner to the client’s location in Peru, facilitating a smooth and efficient project timeline.

As a result of this positive experience, the client has become a long-term cooperation partner with BPM, benefiting from the continued supply of high-quality textured HDPE liners for their mining projects. The partnership is founded on trust, reliability, and the successful collaboration between the client and BPM.

4. Specifications of Textured HDPE Liner for Mining Project in Peru

- Total Quantity – 17,500 m2 Textured Geomembrane

- Thickness – 2.0 mm

- Each roll size – 7m*100m

- One welding machine included for the project

About BPM

As the the professional geomembrane manufacturer and supplier, BPM has been dedicated to supplying one stop geomembranes and services to worldwide customers since its foundation in 2010. Our main innovative, high quality geosynthetics products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. All BPM brand HDPE geomembranes have passed the certificates of the ISO9001, ISO14001, TUV, Soncap, SASO, BV certificates and the test of SGS and Intertek etc. Our geomembrane products have been exported to over 36 countries.

BPM geomembranes mainly include Smooth Geomembrane, Textured Geomembrane, Composite Geomembrane, etc. BPM is also providing professional design and installation service. OEM and ODM are also available.