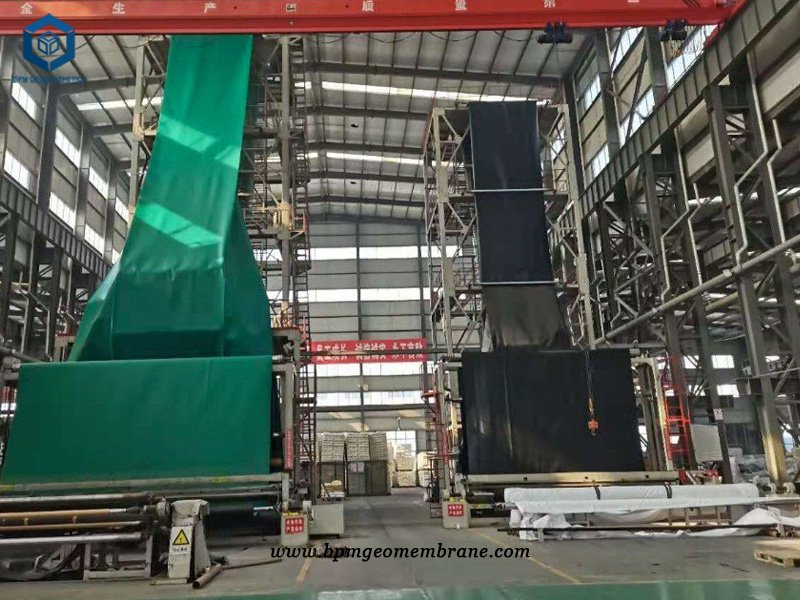

Plastic tank liner, also known as HDPE tank liner, is one of the most durable waterproof geosynthetic materials for tank anti seepage lining solutions. The plastic tank liner is widely used in seawater, freshwater fish and shrimp, mining engineering, garden engineering and salt ponds. BPM geomembrane tank liner adopts fully automated geomembrane liner production equipment and is produced through a three-layer co-extrusion blow molding process. Carbon black, anti-aging agents and stabilizers are added during the production process to greatly enhance the resistance to stress cracking. Anti-puncture ability and anti-ultraviolet ability, and passed the food-grade certification creating the necessary conditions for the healthy growth of fish.

Case Study of Plastic Tank Liner Philippines for Fish Breeding Project

- Location – Philippines

- Products – HDPE Geomembrane Tank Linr

- Application – Fish breeding project

Why Chose Plastic Tank Liner for Fish Breeding Project

Traditional aquaculture in the Philippines uses tarpaulin for farming. The tarpaulin is usually thin, its bursting strength and UV resistance are 12.7% lower than that of geomembrane, and its service life is 1.5 years shorter than that of geomembrane tank liner. We learned about the local culture through conversations with customers. The environment inside the fish pond is poor and it is easy to produce other microorganisms. During the breeding process, there are moss and dirt on the bottom of the fish pond, which is not easy to clean; it causes cross-infection of harmful fungi, and the fish is prone to get sick. Customers are changing the pond and improving the problem of low survival rate of fish.

Solution of Plastic Tank Liner for Fish Breeding Project in Philippines

The local traditional fish ponds in the Philippines are made of tarpaulin. There are many trees in the area where the customer is located, the climate is mild, and the temperature difference between day and night is small, suitable for outdoor breeding. We recommended a 1.0mm plastic tank liner to the customer to install the fish pond. We needed to make 50 fish tanks with a diameter of 5m and a height of 1.5m, requiring a total of 10,000 square meters of geomembrane. We also provided the customer with a specific Installation plan for Plastic Tank Liner

- Cut out a square 5m*5m bottom, 31.4 square meters on the side, and reserve 15 cm of welding edge where it contacts the bottom, and reserve 10-15 cm of overlap edge on the upper part, which is better with wire mesh s contact

- The bottom is backfilled with a 20-30cm soil layer, and the bottom is measured separately to achieve a good anti-seepage effect, and leave enough margin, and use a special HDPE liner welding machine to weld.

After installation, the spacing of each Fish Tank should be between 1.5m and 2.5m.

Considerations of Plastic Geomembrane Liner Installtaion Process

(1) HDPE geomembrane installation for large ponds, multiple geomembranes need to be welded together. When welding, it is required that the splicing is neat, the welding seam is firm and flat, and there is no leakage. At the same time, the other parts of the geomembrane should be checked for possible scratches due to transportation and other parts, and the bottom should be welded and repaired in time.

(2) Area requirements. As the bottom of the fish pond may sink after the water is stored, and the flatness of the bottom of the pond itself is not good enough, there should be room when laying the geomembrane, and it should not be spread too straight and flat.

(3) After the fish pond is laid, try to surround it with bricks with a height of 10cm as far as possible, and use cement to reinforce it.

Benefits of Plastic Tank Liner for Fish Breeding Project in Philippines

(1)High intensity. The tensile strength at yield can reach 18MPa, the tensile strength at break can reach 35MPa, the peel strength is 31kN/m, the shear strength is 33kN/m, and the ductility is good. The elongation at yield is 13% to 16%, and the elongation at break is 700% to 800%. It has good surface compliance and weather resistance. When it really fails, the strain is about 1000%.

(2)Good anti-seepage ability. The anti-seepage coefficient is less than 1×10-13cm/s, which can ensure that the leachate will not leak and contaminate the land due to the liner, rainwater will not pass through the covering layer of the closed site, increase the amount of leachate.

(3)Good chemical stability. Plastic tank Liner is the material with the best chemical stability among all materials. Plastic tank liner has good corrosion resistance.

Specifications of Plastic Tank Liner for Fish Breeding Project in Philippines

- Total plastic tank liner Quantity – 10,000 square meters

- Thickness – 1.0mm

- Roll Size -5.8m * 100m

Summary

BPM Geomembrane has been producing geomembrane tank liner for 11 years. During the production process, we strictly control the quality and the beauty of the winding. We are committed to the best user experience for our customers. We include Indonesia, Kenya, the Philippines, Thailand, Malaysia, and Australia, Chile and other 88 countries. For each customer, we have a plan specially formulated for it, we have a general plan, but we pay more attention to practice, every time we actually inspect all the local conditions of the customer, and strive for the perfect plan, the best method, and the most comfortable It’s our pleasure to develop a plan for each customer, and BPM looks forward to cooperating with you!