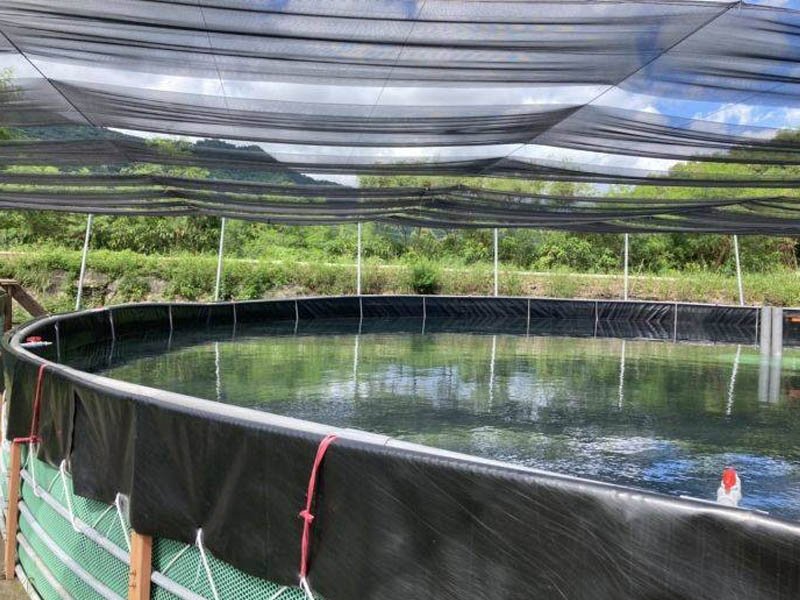

HDPE Pond Liner is widely used in various engineering fields, and the most popular one is the aquaculture field. It is recognized by more and more farmers because HDPE Pond Liner’s good anti-seepage and environmental durability can protect water resources from pollution to the maximum extent, and it is beneficial to the aquaculture of fish and shrimp!

HDPE Pond Liner is called fish pond anti-seepage membrane, but why can it be recognized by more farmers? How To Choose Right HDPE Pond Liner For Fish Farm? BPM Geomembrane is a manufacturer specializing in the production of aquaculture geomembranes. Let us discuss and learn about it in this article.

1. What Are Functions Of HDPE Pond Liner In Fish Farm?

HDPE (High-Density Polyethylene) pond liners play a crucial role in fish farming by providing several functions that contribute to the overall success and efficiency of the fish farm. Some of the key functions of HDPE pond liners in a fish farm include:

1.1 Water Containment

HDPE liners effectively prevent water loss through leakage, ensuring that water levels remain consistent for the fish habitat. This is crucial for maintaining stable environmental conditions necessary for healthy fish growth.

1.2 Contaminant Barrier

These liners stop harmful chemicals and soil pollutants from seeping into the water. By doing so, they protect fish health and ensure the production of high-quality aquaculture products.

1.3 Erosion Control

The liner stabilizes pond banks, minimizing soil erosion caused by water movement. This helps to preserve the pond’s structural integrity, reducing the need for costly repairs.

1.4 Water Quality

HDPE liners maintain clean water by preventing sediment infiltration. Clean water is essential for fish respiration and overall pond ecosystem health.

1.5 Durability

Designed to withstand harsh UV rays, chemical exposure, and mechanical wear, HDPE liners provide long-lasting protection. This durability means less frequent replacements and lower maintenance costs.

1.6 Easy Cleaning

The smooth surface of HDPE liners makes cleaning and maintenance tasks easier. Regular cleaning is vital for controlling algae growth and maintaining water quality.

1.7 Pest Control

Liner systems prevent burrowing animals from penetrating the pond walls. Protecting against such pests helps to sustain the pond’s defenses against environmental threats.

1.8 Economical

Using HDPE liners is a cost-effective solution for long-term fish farming needs. The initial investment in quality liner materials leads to savings on repair and water management costs in the long run.

2. What Are Main Performance Indicators Of HDPE Pond Liner?

The main performance indicators of HDPE pond liners can vary depending on the specific application and requirements of the fish farm. However, some of the key performance indicators to consider when evaluating the quality and effectiveness of an HDPE pond liner are:

2.1 Thickness

- BPM HDPE Pond Liner can be produced with a thickness of 0.2mm-3.0mm to meet different engineering requirements, depending on the pond size and the use environment.

- The greater the thickness, the stronger the impermeability and mechanical damage resistance.

2.2 Tensile Strength

- Reflects the tensile strength of the membrane material, usually ≥15 MPa is better.

- BPM HDPE Pond Liner High tensile strength is conducive to the membrane material to resist external force damage during installation and use.

2.3 Puncture Strength

BPM HDPE Pond Liner has excellent puncture resistance and can resist the roots of most plants.

- Indicates the ability of the membrane material to resist puncture by sharp objects, usually ≥200 N is better.

- BPM Pond Liner High puncture strength helps the membrane material to avoid damage during laying and use.

2.4 Permeability Resistance

- Reflects the anti-permeability ability of the membrane material, and the permeability coefficient is usually ≤1×10-13 cm/s.

- BPM HDPE Pond Liner has Excellent anti-seepage performance can effectively curb the leakage of aquaculture water and groundwater pollution.

2.5 Chemical Resistance

- Reflects the corrosion resistance of the membrane material to chemical substances such as acid, alkali, and salt.

- BPM HDPE Pond Liner has Good chemical resistance can cope with various water quality environments.

2.6 Aging Resistance

- Reflects the aging resistance of the membrane material under environmental factors such as sunlight and temperature changes.

- BPM HDPE Pond Liner has excellent anti-aging, anti-ultraviolet and anti-decomposition capabilities,BPM HDPE Pond Liner has Excellent aging resistance ensures a long service life of the HDPE liner.

3. What Are Considerations For Choosing Suitable HDPE Pond Liner For Fish Farm?

3.1 Pond Size And Depth

- Generally speaking, the larger and deeper the pond is, the thicker and stronger the HDPE pond liner is required.

- For small breeding ponds (less than 500m²), a HDPE pond liner with a thickness of 0.5-1.0mm can be selected.

- For large breeding ponds (more than 500m²), a HDPE pond liner with a thickness of 1.0-2.0mm is required.

3.2 Water Quality Factors And Requirements

- The pH value and salinity in the water will affect the corrosion resistance of HDPE.

- If the water quality is poor (high/low pH value, high salinity, etc.), you need to choose HDPE material with stronger chemical resistance.BPM HDPE Pond liner’s excellent chemical resistance allows it to maintain good anti-seepage function under various water conditions.

3.3 Effect of local climate on the performance

- In cold and rainy areas, BPM HDPE pond liners need good freeze-thaw resistance.

- In windy areas, BPM HDPE pond liners must have sufficient tensile strength.

- In hot and dry areas, BPM HDPE pond liners must have excellent aging resistance.

3.4 Transportation And Installation

- If long-distance transportation is required, the thickness of the HDPE Pond Liner must be sufficient to withstand various mechanical damage.

- During on-site construction, BPM HDPE pond liner have a high puncture strength to resist sharp objects

4. What Are Installation Points Of HDPE Pond Liner In Fish Farm?

4.1 Unrolling the Liner

Carefully unroll the HDPE liner onto the prepared base. Take care to avoid folds or wrinkles, as these can lead to leaks or damage, compromising the liner’s integrity.

4.2 Seaming Multiple Sheets

If your pond requires more than one sheet of liner, seam them together using heat welding or another effective method. This ensures a watertight seal, preventing leaks and maintaining proper water levels.

4.3 Anchoring the Edges

Secure the edges of the liner with soil, rocks, or other materials. This anchoring prevents the liner from shifting or lifting, which could cause tears or separate important seams.

4.4 Leak Testing

Once the liner is in place, perform a thorough water test to identify any leaks or weaknesses. Fill the pond partially and monitor closely for any significant drop in water level, ensuring the liner is functioning correctly.

4.5 Applying a Protection Layer

Cover the liner with a protective layer of soil or another suitable material. This extra layer shields the liner from UV damage, mechanical wear, and potential harm from animals, extending its lifespan and improving durability.

4.6 Ongoing Maintenance

Regular inspections and maintenance are crucial for maintaining the liner’s condition. Check for signs of damage, clean the liner, and remove debris or vegetation to prevent them from causing harm and affecting water quality.

5. Summary

BPM HDPE pond liner can effectively meet the anti-leakage needs of different farms and provide reliable infrastructure support for aquaculture. If you have any other questions, please feel free to communicate with me.