BPM newly developed and engineered HDPE textured geomembrane has been successfully put into production in February, 2019. Our specially designed HDPE textured geomemrbane liner production line and manufacturing process is the ideal geotechnical product for landfill and waste containment applications.

BPM has always been responsible for develop best HDPE geomembrane products and best services for your requirements. In order to improve the supply capacity and satisfy project requirements of landfill and mining applications, etc, BPM has developed a new HDPE textured geomembrane production technology.

1.What Is HDPE Textured Geomembrane?

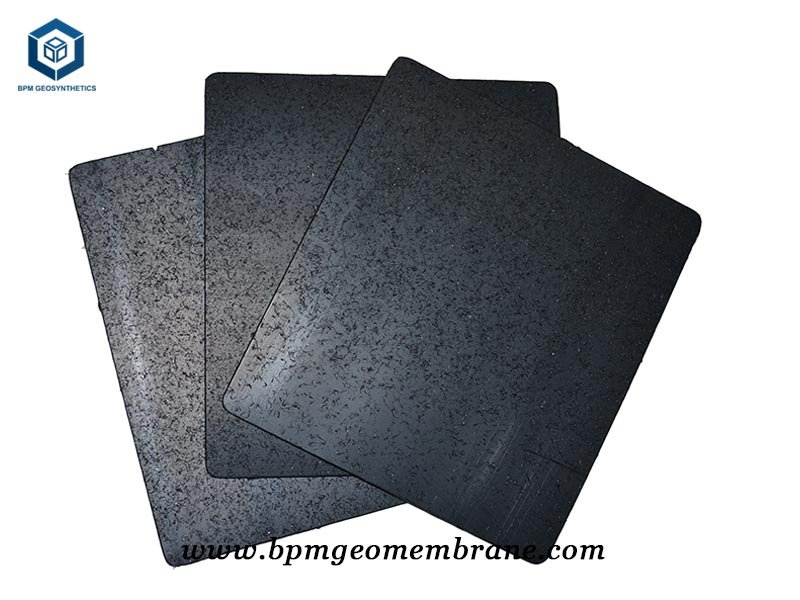

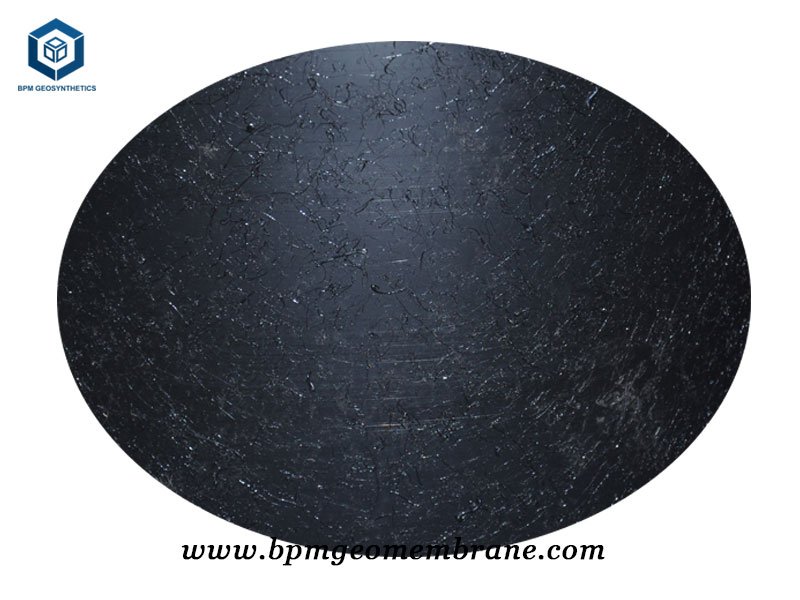

HDPE textured geomembrane is a type of geomembrane that is manufactured using high-density polyethylene (HDPE) material and has a surface with raised studs or embossed patterns. These patterns are designed to provide additional friction and improve the liner’s performance in terms of stability, slope protection, and resistance to slippage.

During the manufacturing process of HDPE textured geomembrane, a pattern of raised features is created on the surface. These features can vary in shape, size, and pattern, depending on the specific manufacturing technique used and the intended application of the geomembrane.

2.What Are Characteristics of HDPE Textured Geomembrane?

HDPE textured geomembranes possess several key characteristics that make them suitable for various applications. Here are some common characteristics of HDPE textured geomembranes:

2.1 Frictional Properties

The textured surface of HDPE geomembranes provides increased frictional resistance, which helps to prevent slippage and maintain stability. The raised studs or embossed patterns enhance the liner’s ability to grip adjacent materials, such as soil or other geosynthetics, reducing the risk of sliding or shifting.

2.2 Shear Resistance

The texturing on the geomembrane enhances its shear resistance, making it more effective in preventing soil or material displacement. This characteristic is especially crucial in applications where the geomembrane is in contact with sloping or inclined surfaces, providing added stability and preventing potential failures.

2.3 Surface Protection

The textured surface offers improved protection against external factors such as UV radiation, abrasion, and punctures. The raised studs or patterns act as a cushioning effect, reducing direct contact with potentially damaging objects or surfaces. This enhances the geomembrane’s durability and lifespan.

2.4 Flexibility

HDPE textured geomembranes are known for their flexibility, allowing them to conform to irregular surfaces and accommodate dynamic conditions, such as ground settlement or movement. This flexibility simplifies install and ensures effective coverage, even in challenging terrain.

2.5 Chemical Resistance

HDPE geomembranes, including textured variants, exhibit excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This resistance ensures the geomembrane’s integrity and prevents degradation or damage when exposed to various chemicals commonly found in environmental and industrial applications.

2.6 UV Resistance

HDPE textured geomembranes are typically manufactured to be UV resistant, meaning they can withstand prolonged exposure to sunlight without significant degradation. This characteristic is crucial for applications where the geomembrane is exposed to direct sunlight, such as in outdoor installations or landfills.

2.7 Customizability

HDPE textured geomembranes can be customized to meet specific project requirements, including the choice of texture pattern, thickness, and width. This versatility allows for tailored solutions that suit the demands of various applications.

3.How Is HDPE Textured Geomembrane Produced?

HDPE textured geomembranes are typically produced through a manufacturing process that involves several steps. Here is a general overview of how HDPE textured geomembranes are produced:

3.1 Material Preparation

HDPE resin, the primary material for the geomembrane, is carefully selected and prepared. The resin pellets are melted and blended with additives like antioxidants, UV stabilizers, and processing aids to enhance the material’s properties.

3.2 Extrusion

The prepared HDPE material is fed into an extruder, a machine that melts the resin and forms it into a continuous sheet. Through the application of heat and pressure, the molten resin is forced through a flat die, resulting in a uniform sheet.

3.3 Texturing

The textured pattern is imparted onto the HDPE sheet during the extrusion process. This is achieved by using embossing rolls or plates with the desired pattern. These rolls or plates press against the hot HDPE sheet, transferring the pattern onto the surface.

3.4 Cooling and Sizing

After the texturing process, the textured HDPE sheet is rapidly cooled to solidify it. Cooling can be achieved through contact with cooled rollers or immersion in a water bath. Once cooled, the sheet is trimmed to the desired width and cut into rolls of appropriate length.

3.5 Quality Control

Throughout the production process, rigorous quality control measures are implemented to ensure dimensional accuracy, uniform thickness, and overall product quality. Parameters such as temperature, pressure, and dimensions are continuously monitored. Additionally, off-line testing is conducted to assess mechanical properties and other performance characteristics.

3.6 Packaging and Storage

The finished HDPE textured geomembrane rolls are carefully packaged and labeled for transportation. They are stored in a controlled environment to shield them from UV exposure, moisture, and potential damage before reaching end-users or distributors.

4.What Are Textured HDPE Geomembranes Used for?

Textured HDPE geomembranes have a wide range of applications. They are used for environmental containment, pond and reservoir lining, mining and heap leach pads, agriculture and aquaculture, secondary containment, civil engineering and construction, as well as waterproofing and roofing. These geomembranes provide enhanced frictional properties, stability, and protection against seepage, erosion, and chemical corrosion.

In environmental applications, they are used to line landfills and waste storage facilities. They are also employed for pond and reservoir lining in water storage structures. In addition, they find use in mining and agriculture for containment and erosion control. In construction, they are used for slope stabilization and canal lining. Lastly, they serve as effective barriers in secondary containment and waterproofing projects.

5.About BPM

BPM is the professional geosynthetics manufacturer and wholesaler. Our main innovative, high quality geosynthetic products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. BPM brand geosynthetic product had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV certificates and passed the test of SGS and Intertek, etc. Our geosynthetic products have exported to over 100 countries.

If you have any questions or inquiries, please contact us, we will reply as soon as possible.