HDPE geomembrane pond liners Australia is specifically designed for use in water retention and containment in the big reservoir, farm pond, and lake applications. BPM geomembrane products are specially deigned and manufactured with special stabilizers providing enhanced UV, heat, and chemical resistance. With our state-of-the-art facilities and skilled installation team, we manufacture, fabricate, and install a wider variety of geomembranes than most other providers. BPM specializes in geomembranes for all containment applications.

1 CASE STUDY of HDPE Geomembrane Pond Liners Australia for Landfill Project

- Location : Australia

- Product(s) : HDPEGeomembrane Pond Liners

- Application : Landfill Project

2 Why Chose HDPE Geomembrane Pond Liners Australia for Landfill Project

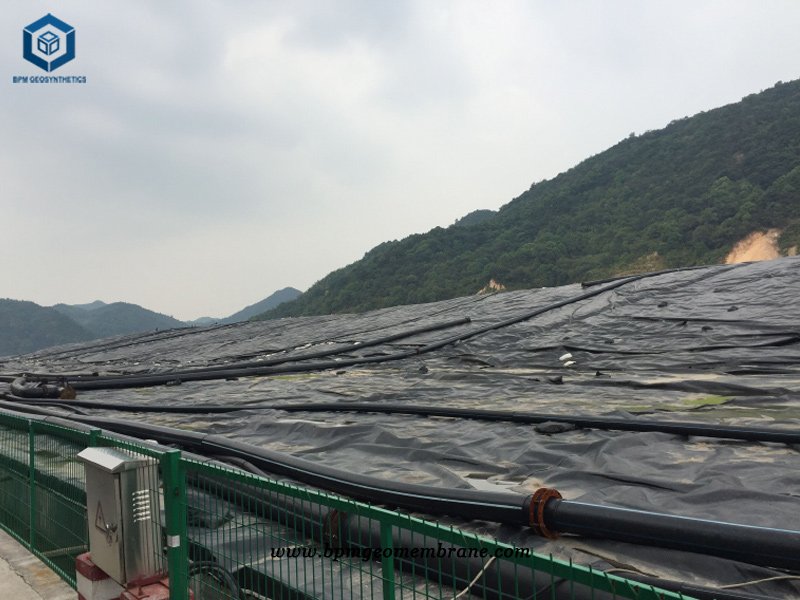

Located in South Australia, the landfill project of our Australian client emphasizes the critical issue of leakage, which poses significant environmental risks. Soil contamination resulting from leakage can lead to salinization and poisoning, with potential health hazards for individuals exposed to the contaminated soil. The presence of parasites and pathogenic bacteria further exacerbates the risk of illnesses. Moreover, infiltration can pollute groundwater, potentially entering the human food chain and causing severe harm to human health. Our Australian client seeks an expeditious and effective HDPE geomembrane pond liners Australia solution to address this pressing problem, recognizing the urgent need for a suitable resolution.

3 How To Use HDPE Geomembrane Liners Australia

High density polyethylene geomembrane pond liner is the most widely used material in the anti-seepage engineering of garbage sanitary landfills. The main parts used are the bottom liner of the landfill, the closure cover of the landfill, and the liner of the leachate adjustment tank.

Since the 1980s, high density polyethylene geomembrane pond liners Australia with a thickness of 1mm to 2 mm have been used in landfill anti-seepage treatment in foreign countries. It has become a mature technology and has been increasingly used. my country’s environmentally friendly landfills started late, but in recent years, under the attention of the State Environmental Protection Administration and the increase in national environmental awareness, environmentally friendly landfills with High density polyethylene geomembrane treatment have been widely used throughout the country. Therefore, we recommend that customers use 1.5mm glossy high density polyethylene geomembrane to cover the landfill.

The main features and advantages of high density polyethylene geomembrane for landfill are:

- High intensity. The tensile strength at yield can reach 18MPa, the tensile strength at break can reach 35MPa, the peel strength is 31kN/m, the shear strength is 33kN/m, and the ductility is good. The elongation at yield is 13% to 16%, and the elongation at break is 700% to 800%. It has good surface compliance and weather resistance. When it really fails, the strain is about 1000%.

- Good anti-seepage ability. The anti-seepage coefficient is less than 1×10-13cm/s, which can ensure that the leachate will not leak and contaminate the land due to the liner, rainwater will not pass through the covering layer of the closed site, increase the amount of leachate, and landfill gas will not pass through the liner Pad and leak out.

- Good chemical stability. Because the maximum temperature of the landfill can reach 50°C, chemical stability is the most critical factor in the design of the landfill. HDPE geomembranepond liner is the material with the best chemical stability among all geomembrane materials. The chemical composition of the leachate of the municipal solid waste sanitary landfill does not pose a threat to HDPE liners. HDPE geomembrane has good corrosion resistance.

The softening point of high-density polyethylene geomembrane is about 121℃, and the cold embrittlement point is about -120℃. It has strong resistance to inorganic acids, organic acids, inorganic salts, alcohols, aldehydes, amines, esters, and greases. It can prevent the direct corrosion of these chemicals and prevent performance degradation due to absorption and expansion. , It also has a certain resistance to certain carbon and oxygen compounds (such as benzene, phenylacetaldehyde, hexane and formaldehyde), and only has poor resistance to halogenated carbon and oxygen compounds (such as chlorinated benzaldehyde and bromobenzene).

The performance of the high-density polyethylene geomembrane is good. The durability of the high-density polyethylene geomembrane buried in the soil and underwater can reach more than 50 years.

BPM expert group discussed with Australian engineering designers in a video conference, and finally selected 1.5mm high-density polyethylene geomembrane pond lienr as the main product for covering the landfill.

4 Benefits of HDPE Geomembrane Landfill Liners Australia

High Density Polyethylene (HDPE) is the high density version of PE plastic and is harder and denser than the LDPE.High Density Polyethylene (HDPE) Geomembrane has proved to be a boon especially for developing countries by playing an important role to prevent the air and groundwater pollution. The best thing is that it can be easily moulded and welded together and the use of UV Stabilizers improves its weather resistance. HDPE geomembrane pond liner lives up to the expectations which are demanded in today’s world of environmental engineering. BPM High Density Polyethylene geomembrane’s prime motive is to keep the nature clean.

This project is a hazardous waste landfill, so the selection of HDPE geomembrane pond liners Australia is particularly strict. As the most important part of the anti-seepage system, the quality and construction quality of the High Density Polyethylene geomembrane liner directly affects the success or failure of the entire anti-seepage project.

5 HDPE Geomembrane Landfill Liners Australia Features

The project uses BPM High Density Polyethylene geomembrane (double-smooth). The High Density Polyethylene Geomembrane has the following features.

- Made of 100% brand new special HDPE resin.

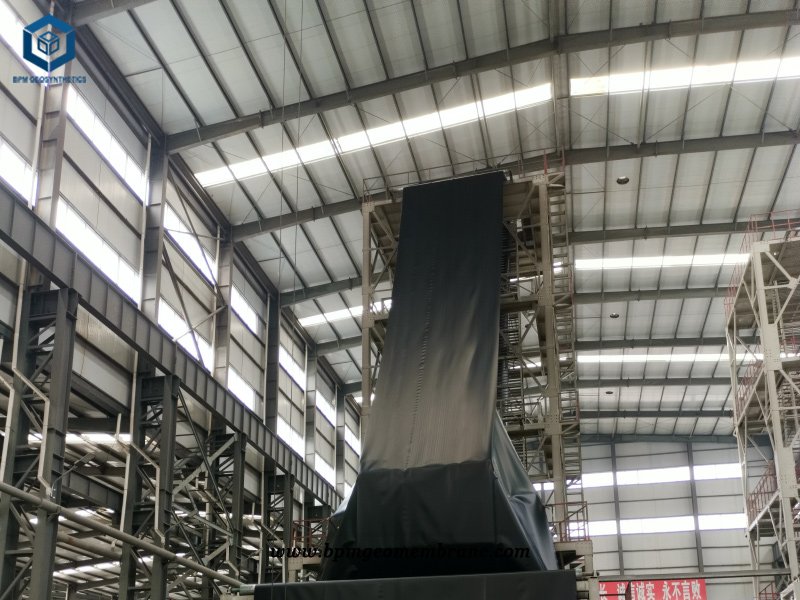

- The Best ProjectMaterial Co., Ltd. is a leading manufacturer of blow molding process HDPE geomembrane pond liners in China.

- BPM High Density Polyethylene geomembrane has passed the GAI-LAP laboratory certification of the International Geosynthetics Research Institute.

- It has excellent durability and resistance to environmental stress cracking (>3000 hours) to reach the highest detection value in the industry.

Specifications of HDPE Geomembrane Pond Liners Australia for Landfill Project

- Total Geomembrane pond liner quantity – 26,0000 squares meters

- Geomembrane Thickness – 1.5mm

- Each roll size is 7m*140m

About BPM

As the the professional geomembrane manufacturer and supplier, BPM has been dedicated to supplying one stop geomembranes and services to worldwide customers since its foundation in 2010. Our main innovative, high quality geosynthetics products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. All BPM brand HDPE geomembranes have passed the certificates of the ISO9001, ISO14001, TUV, Soncap, SASO, BV certificates and the test of SGS and Intertek etc. Our smooth geomembrane liner and textured geomembrane liner products have been exported to over 36 countries. If you have any questions or inquiries, please contact us.