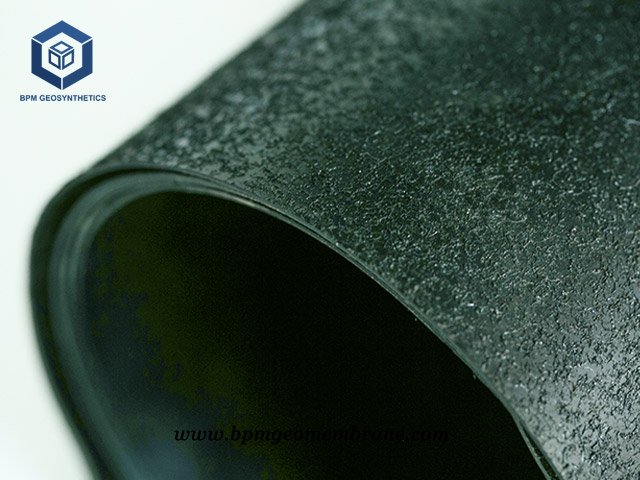

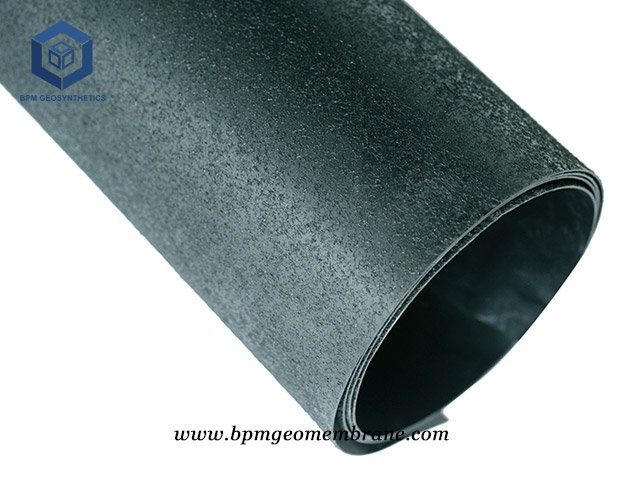

Textured HDPE Geomembrane is the ideal geotechnical material as high friction lining materials of channels, dams and waste containment structures. BPM textured geomembranes are manufactured to the highest quality standards, ensuring exceptional durability. They are packaged in double woven geotextile and strength belts for added protection. With thickness options ranging from 1.2mm to 3.0mm, BPM textured HDPE geomembranes are suitable for projects requiring increased friction and steeper slopes, such as landfills, mining operations, retaining backfills, and waste containment. Our textured geomembranes have obtained certifications including ISO9001, ISO14001, TUV, Soncap, SASO, BV, and have passed rigorous testing by SGS and Intertek, among others.

1. What Is Textured HDPE Geomembrane?

Textured HDPE geomembrane is a type of geomembrane that is specifically designed and manufactured with a rough surface on one or both sides. This texture greatly improves the friction coefficient, making it highly suitable for applications involving steep slopes and vertical engineering designs. The textured surface also facilitates high-quality thermal fusion welding between adjacent sheets, as they have smooth edges.

Textured HDPE geomembrane is engineered with excellent superior shear strength and multi-axial performance. It exhibits high shear strength, significant friction angles, excellent elongation properties, and the highest interface surface friction coefficient. These characteristics contribute to enhanced interface strength when in contact with soils, textiles, geosynthetic clay liners, and other critical interfaces.

The degree of texturing in the geomembrane is determined using the ASTM D7466 standard test method. This method measures the height from the core membrane to the top of the texture peak, providing a standardized measurement for assessing the level of texturing.

Textured HDPE geomembranes are widely used in various applications, including slope protection, waste containment, dam lining, and other projects where increased friction and interface strength are required. They provide an effective solution for maximizing the volume and performance of the geomembrane in challenging engineering and environmental conditions.

2. Specifications of Textured HDPE Geomembrane

| Test Properties | Unit | Standard | Test frequency | GSO10 | GSO15 | GSO20 | GSO25 |

|---|---|---|---|---|---|---|---|

| Thickness | mm | D5994 | per roll | 1.00 | 1.50 | 2.00 | 2.50 |

| Asperity Height | mm | D7446 | Every 2nd roll (2) | 0.25 | |||

| Density | g/cc | D1505/D792 | 90,000kg | 0.94 | |||

| Tensile Properties | |||||||

| Yield Strength | KN/m | D6693

Type IV |

9,000 kg | 15 | 22 | 29 | 37 |

| Break Strength | KN/m | 10 | 16 | 21 | 26 | ||

| Yield Elongation | % | 12 | 12 | 12 | 12 | ||

| Break Elongation | % | 100 | 100 | 100 | 100 | ||

| Tear Resistance | N | D1004 | 20,000kg | 125 | 187 | 249 | 311 |

| Puncture Resistance | N | D4883 | 20,000kg | 267 | 400 | 534 | 667 |

| Stress Crack Resistance | hr | D5397(App) | per GRI GM-10 | 300 hr | |||

| Carbon black content | % | D4218 | 9,000kg | 2.0-3.0% | |||

| Carbon black dispersion | D5596 | 20,000kg |

For 10 different views: 9 in Categories 1 or 2 and 1 in Category 3 |

||||

| Oxidative Induction Time | |||||||

| Standard OIT | min | D3895 | 90,000kg | 100 min | |||

| High pressure OIT | D5885 | 90,000kg | 400 min | ||||

| Oven Aging at 85°C retained after 90 days | % | D5721 | per each formulation | 55% | |||

| Standard OIT | D3895 | 80% | |||||

| High pressure OIT | D5885 | 80% | |||||

| UV Resistance | |||||||

| High Pressure OIT – % retained after 1600 hrs | % | D5885 | per each formulation | 50% | |||

| Roll Width | m | 7 | 7 | 7 | 7 | ||

| Roll Length | m | 210 | 140 | 105 | 70 | ||

| Size stability | % | 2% | |||||

3. What Are Features of HDPE Textured Geomembrane?

HDPE textured geomembranes offer features such as a textured surface, UV and chemical resistance, stress crack resistance, high tensile strength, low elongation, corrosion and aging resistance, impermeability, antifouling properties, easy construction, OEM/ODM availability, and favorable pricing. These features make HDPE textured geomembranes suitable for a wide range of applications, including containment, environmental protection, and hydraulic engineering projects.

3.1 Textured Surface

HDPE textured geomembranes can be manufactured with a textured surface on one or both sides, depending on the specific requirements of the project. The textured surface provides increased frictional coefficient, making it ideal for applications that involve steep slopes. The enhanced friction helps to stabilize the geomembrane and prevent slippage.

3.2 Ultraviolet and Chemical Resistance

HDPE textured geomembranes exhibit excellent resistance to ultraviolet (UV) radiation and a wide range of chemicals. This makes them highly durable and suitable for outdoor applications where exposure to sunlight and chemical substances is expected.

3.3 Stress Crack Resistance

These geomembranes have excellent resistance to stress cracking, which is crucial for ensuring long-term performance and preventing leaks or failures due to stress-induced cracks. This feature enhances the overall reliability and lifespan of the geomembrane.

3.4 High Tensile Strength and Low Elongation

HDPE textured geomembranes offer high tensile strength, allowing them to withstand substantial mechanical stress and strains. Additionally, they have low elongation properties, which means they exhibit minimal stretching under tension, making them more resistant to deformation and damage.

3.5 Corrosion and Aging Resistance

HDPE textured geomembranes are highly resistant to corrosion and aging. They can withstand exposure to various environmental factors, such as moisture, chemicals, and temperature fluctuations, without significant degradation. This resistance ensures long-term performance and longevity.

3.6 Impermeable and Antifouling

The textured surface of these geomembranes enhances their impermeability, making them highly effective in preventing the leakage or seepage of liquids or gases. Additionally, the textured surface helps resist fouling, reducing the accumulation of unwanted substances on the geomembrane.

3.7 Easy Construction and Good Overall Continuity

HDPE textured geomembranes are easy to install and provide good overall continuity. Their flexibility and adaptability simplify the installation process, ensuring a seamless and reliable liner system.

3.8 OEM/ODM Availability

Manufacturers of HDPE textured geomembranes often offer OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. This means they can customize the geomembranes according to specific project requirements, providing tailored solutions.

3.9 Best Factory Price

HDPE textured geomembranes are available at competitive factory prices, making them a cost-effective choice for various applications.

4. What Is The Difference Of Smooth vs Textured Geomembrane?

Both smooth and textured geomembranes are cost-effective geosynthetic materials used in various projects related to environmental protection, water and waste containment, and seepage prevention. However, there are some key differences between the two.

4.1 Textured geomembrane

Textured geomembranes are designed with one or two rough surfaces. The textured surface provides increased frictional coefficient, making it preferable for slope applications where enhanced traction is needed. It is commonly used for slope anti-skid and seepage prevention purposes. Examples of projects where textured geomembranes are used include landfill closures, tailings ponds, and similar applications. It is important to note that textured geomembranes typically have a higher price compared to smooth geomembranes due to the additional manufacturing process involved in creating the textured surface.

4.2 Smooth geomembrane

Smooth geomembranes, as the name suggests, have a smooth surface without any texturing. They are commonly used as impermeable barriers in projects such as landfill bottoms, artificial lakes, reservoirs, and other applications where a seamless and smooth impermeable layer is required.

The main difference between smooth and textured geomembranes lies in their surface characteristics and preferred applications. Textured geomembranes offer enhanced friction and anti-skid properties, making them suitable for slope applications, while smooth geomembranes provide a seamless and smooth impermeable layer, making them ideal for applications where a smooth surface is desired.

5. What Is Textured HDPE Geomembrane Used For?

Textured HDPE geomembrane is specially designed and fabricated for landfills and mining applications due to its advanced stabilization, excellent interface friction coefficient and inherent flexibility. As flexibility as our other geomembranes, textured HDPE geomembranes have been widely in backfilled liner, retaining backfill on steep side, heap leach pads, landfill and pad base liner, water conservancy applications such as dam, reservoirs, sewage pools, swimming pools, buildings, underground buildings, garbage dumps and mining projects.

6. What Are The Advantages Of Textured Geomembrane for Slope projects?

Textued geoemmbrane is designed and engineered with textured surface on one or both sides which offers inforced friction. In slope protection projects, textured geomembranes provide advantages such as enhanced friction, improved drainage performance, effective soil erosion prevention, wide applicability in slope projects, and long-term performance. These advantages make them a reliable and effective choice for protecting slopes in various environments.

6.1 Enhanced Friction

The textured surface of the geomembrane provides increased frictional coefficient. This enhanced friction plays a crucial role in slope stability by improving the interface between the geomembrane and the soil. It helps to prevent slippage and soil erosion, providing greater stability to slopes.

6.2 Drainage Performance

The texture on the surface of the geomembrane allows for effective drainage of water. This is particularly important in slope projects, as proper drainage helps to mitigate the buildup of excess water and prevents the saturation of the soil. Effective drainage reduces the risk of landslides and maintains the stability of the slope.

6.3 Soil Erosion Prevention

Textured geomembranes are highly effective in preventing soil erosion. The increased friction and drainage performance of the textured surface help to retain the soil in place, even under the influence of heavy rainfall or water flow. By minimizing soil erosion, textured geomembranes contribute to the long-term stability and integrity of the slope.

6.4 Widely Applicable

Textured geomembranes can be used in a variety of slope protection projects. They are commonly employed in mountainous areas, riverbanks, and other locations prone to soil erosion and landslides. The versatility of textured geomembranes makes them suitable for different types of slopes and soil conditions.

6.5 Long-Term Performance

Textured geomembranes are designed for longevity and durability. They are manufactured using high-quality materials that offer excellent resistance to UV radiation, chemicals, and physical stresses. This ensures that the geomembrane maintains its performance and integrity over an extended period, providing long-term slope protection.

7. About BPM Geomembrane

BPM Geomembrane had provided many types of effective and states of the art geomembrane and other geosynthetics to over 81 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

BPM is not only manufacturing best quality geomembrane products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.