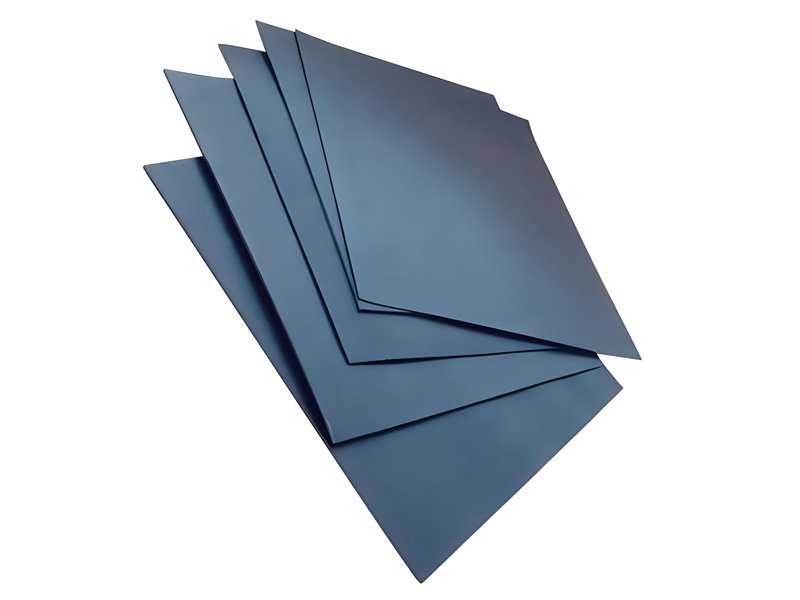

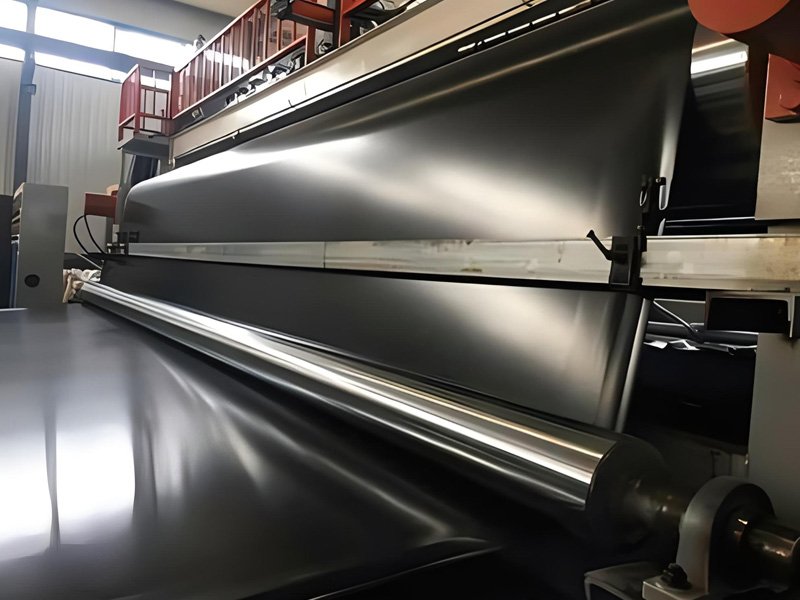

LLDPE geomembrane, also known asgeomembrana LLDPE, is a low linear density polyethylene liner which provides super tensile strength, flexibility and excellent resistance to low temperatures and UV exposure. This high-quality and cost-effective geosynthetic material is designed for longevity, high strength and durability. As the leading manufacturer and supplier of geomembranes, BPM Geomembrane offers customized LLDPE geomembranes ranging from 20 to 120 mils in thickness, available in both smooth and textured variations. The BPM LLDPE liner is ideal for applications prioritizing superior flexibility and elongation in pond liner, containment, or wastewater applications.

1. What Is A LLDPE Geomembrane?

LLDPE geomembrane is manufactured from first quality single source, compoundedvirgin polyethylene resins. BPM LLDPE contains no additives, fillers, extenders or plasticizers which can migrate to the surface causing premature aging. This liner contains approximately 97.5% polymer and 2.5% carbon black, anti-oxidants and heat stabilizers.

BPM LLDPE geomembrana liner surpasses the requirements set by the GRI-GM17 standard. LLDPE liners are available in thicknesses ranging from 20 to 120 mils and offer both textured and conductive options. LLDPE geomembrane is custom fabricated to size and specifications, LLDPE geomembrane can be procured in various colors to suit specific project needs.

LLDPE geomembrane has remarkable flexibility, a characteristic that simplifies installation by reducing the need for cutting and minimizing the risk of punctures during the process. Geomembrana LLDPE can be both extrusion and wedge welded for larger applications including water, wastewater , waste containment uses that require greater flexibility and elongation performance.

2. Specifications Of LLDPE Geomembrane?

| PROPERTIES | Test Method | Unit | BPM50 | BPM75 | BPM100 | BPM150 | BPM200 | BPM250 |

| Thickness (min. avg) | ASTM D 5199 | mm | 0.5 | 0.75 | 1 | 1.5 | 2 | 2.5 |

| Thickness (lowest individual reading) | ASTM D 5199 | mm | 0.45 | 0.67 | 0.9 | 1.35 | 1.8 | 2.3 |

| Density(min) | ASTM D 1505 | g/ cm3 | 0.92 | 0.92 | 0.92 | 0.92 | 0.92 | 0.92 |

| Tensile Properties (min. avg) | ASTM D 6693 | |||||||

| Strength at Break | kN/m | 14 | 20 | 27 | 40 | 55 | 66 | |

| Elongation at Break | % | 800 | 800 | 800 | 800 | 800 | 800 | |

| Tear Resistance (min. average) | ASTM D 1004 | N | 50 | 70 | 100 | 150 | 200 | 250 |

| Puncture Resistance (min. avg) | ASTM D 4833 | N | 120 | 190 | 250 | 370 | 500 | 620 |

| Carbon Black Content (min. avg) | ASTM D 1603 | % | 2 | 2 | 2 | 2 | 2 | 2 |

| Carbon Black Dispersion (min. avg) | ASTM D 5596 | Cat. 2 | Cat. 2 | Cat. 2 | Cat. 2 | Cat. 2 | Cat. 2 | Cat. 2 |

| Low Temperature Brittleness | ASTM D 746 | ˚ C | < -77 | < -77 | < -77 | < -77 | < -77 | < -77 |

| Oxidative Induction Time (OIT) (min. avg) | ASTM D 3895 | minutes | 100 | 100 | 100 | 100 | 100 | 100 |

| Melt Flow Index (190 ° C, 2.16kg) | ASTM D 1238 | g/10 min | < 1.0 | < 1.0 | < 1.0 | < 1.0 | < 1.0 | < 1.0 |

| 2% Modulus | ASTM D 5323 | kN/m | 210 | 370 | 420 | 630 | 840 | 1050 |

| Dimensional Stability (100 ˚ C, 1 hr) | ASTM D 1204 | % | ± 1 | ± 1 | ± 1 | ± 1 | ± 1 | ± 1 |

| Axi-Symmetric Break Strain | ASTM D 5617 | % | 56 | 56 | 56 | 56 | 56 | 56 |

| Low Temperature Brittleness | ASTM D 746 | ˚ C | < – 77 | < -77 | < -77 | < -77 | < -77 | < -77 |

3. What Are The Benefits of LLDPE Geomembrane?

LLDPE geomembrane offers a multitude of benefits that make it an excellent choice a reliable and versatile choice for a wide range of applications, providing effective containment and lining solutions.

3.1 Lowest permeability

LLDPE geomembrana liner provides an effective barrier against the passage of liquids and gases. This property ensures reliable containment and prevents leakage.

3.2 Superior flexibility

LLDPE geomembrane offers supper flexibility to conform to irregular surfaces and withstand movements, settlements, and differential settlement without compromising its integrity.

3.3 Outstanding stress crack capacity

LLDPE geomembrana can resist the growth and propagation of cracks under stress. This feature contributes to its long-term performance and durability in demanding environments.

3.4 Excellent UV and chemical resistance

LLDPE geomembrane can withstand prolonged exposure to sunlight without degrading or losing its effectiveness. Additionally, it is resistant to a wide range of chemicals, ensuring its durability in chemically aggressive environments.

3.5 High puncture resistance

LLDPE geomembrane provides a strong barrier against puncture hazards, such as sharp objects, ensuring the long-term integrity of the geomembrane.

3.6 Meets or exceeds all aspects of the GRI-GM17 industry standard.

his ensures that LLPDE liner meets strict quality and performance requirements, providing confidence in its performance.

3.7 Good weldability

The LLDPE geomembran allows for efficient and reliable seam connections during installation. This ensures the integrity of the liner system and minimizes the risk of leakage.

3.8 Easy To Install

LLDPE geomembrane is easy to install due to its flexibility, manageable weight, and weldability. Its installation process is straightforward, saving time and effort during the project.

3.9 OEM/ODM availability

LLDPE geomembrane is available with OEM/ODM options, allowing for customization based on specific project requirements. This ensures that the geomembrane can be tailored to meet the desired specifications.

3.10 Best factory price

BPM LLDPE geomembrane providing a cost-effective solution for containment and lining applications without compromising quality and performance.

4. What Is The Difference Between HDPE and LLDPE Geomembrane?

The key difference between HDPE (High-Density Polyethylene) and LLDPE (Linear Low-Density Polyethylene) geomembrane lies in their molecular structure and resulting physical properties.

4.1 Flexibility

LLDPE geomembrane is more flexible than HDPE geomembrane. LLDPE can withstand folding and compound bending without sustaining damage or compromising its integrity. On the other hand, HDPE is stiffer and less flexible, making it more prone to damage if folded or bent beyond its yield point.

4.2 Yield Point

LLDPE geomembrane has a higher elongation capacity and stress crack resistance compared to HDPE. This means LLDPE can stretch further without breaking or cracking, allowing it to adapt to irregular surfaces and withstand movements and settlements more effectively.

4.3 Cost and Price

HDPE geomembrane tends to have a lower cost compared to LLDPE geomembrane. The price difference is primarily due to the manufacturing process and the difference in material properties.

4.4 Applications

HDPE geomembrane is commonly used in applications where stiffness and rigidity are preferred or required, such as landfill caps, landfill cells, and industrial containment. LLDPE geomembrane, with its superior flexibility, is often used in applications that require adaptability to irregular surfaces, differential settlement management, and excellent puncture resistance, such as exposed or effluent ponds, wastewater containment, and irrigation ponds.

5. What Is LLDPE Geomembbrane Used For?

LLDPE geomembrane is widely used in various applications where reliable containment and protection against liquid or gas permeation are required.

5.1 Exposed or Effluent Ponds

LLDPE geomembrane is used to line ponds that store effluent or wastewater, providing a reliable barrier to prevent leakage and protect the surrounding environment.

5.2 Storm Water Collection Ponds

LLDPE geomembrana is employed in the construction of stormwater collection ponds to ensure proper containment of runoff water, preventing infiltration into the ground.

5.3 Waste Containment

It is used in waste facilities, including containment ponds, tanks, and basins, to prevent the seepage of contaminants into the surrounding soil and groundwater.

5.4 Irrigation Ponds, Canals, Water Reservoirs, and Ditches

LLDPE geomembrane is utilized to line irrigation ponds, canals, water reservoirs, and ditches, ensuring efficient water storage, preventing seepage, and maximizing water availability for agricultural or industrial purposes.

5.5 Landfill Cells, Covers, and Caps

LLDPE geomembrane is a crucial component in landfill engineering, where it is used to line landfill cells, covers, and caps to prevent the migration of leachate and gas, protecting the environment from contamination.

5.6 Wastewater Lagoons and Treatment Plants

LLDPE geomembrane is employed in the construction of wastewater lagoons and treatment plants to provide reliable containment and prevent seepage of wastewater into the surrounding soil and water bodies.

5.7 Industrial Containmen

It is used in various industrial applications to contain and control liquids, chemicals, or hazardous materials, ensuring environmental protection and safety.

5.8 Golf Course and Decorative Ponds

LLDPE geomembrane is used in the construction of golf course ponds and decorative water features to provide waterproofing and prevent water loss.

5.9 Liquid Storage Tanks

LLDPE geomembrane can be used as a liner for liquid storage tanks, providing a reliable barrier against leakage and maintaining the integrity of the stored liquids.

5.10 Environmental Containment

LLDPE geomembrane is utilized in environmental containment projects, such as capping and lining contaminated sites or creating barriers to prevent the migration of pollutants into the surrounding environment.