Composite geomembrane liner combines the advantages of geotextiles and geomembranes in a single product. This integration allows for enhanced performance and functionality, as the geotextile layer provides additional properties such as filtration, separation, reinforcement, and drainage, while the geomembrane layer ensures impermeability. This composition makes it possible to obtain a geomembrane with specific properties in addition to reducing the manipulations and the time required for the installation of a multilayer system.

Composite geomembrane liners combine the benefits of geotextiles and geomembranes to provide a versatile solution for impermeable barriers. It is widel used in various industries, including landfill management, wastewater treatment, road construction, aquaculture, landscaping, agriculture, and more.Its versatility and effectiveness make it a preferred choice for projects requiring impermeability, durability, and protection against environmental hazards.

As the leading geomembrane manufacturer and supplier, BPM offers high quality custom composite geomembrane for you needs at best factory price.

1. What Is A Composite Geomembrane Liner?

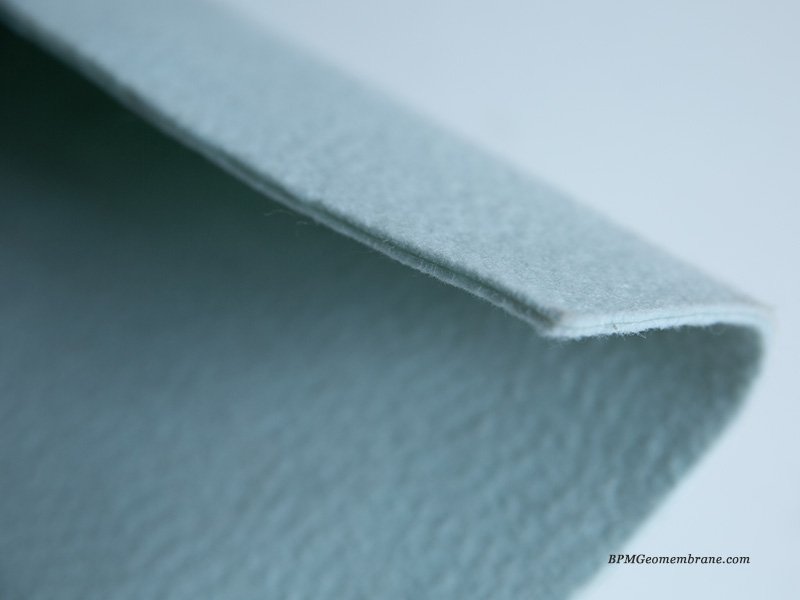

Composite Geomembrane Liner is a specialized material that combines geotextiles and geomembranes to create an impermeable barrier for various applications. It is produced by heat-bonding nonwoven or woven geotextile layers to HDPE geomembranes using calendaring processing technology.

BPM brand composite Geomembrane liner, for example, is manufactured by pressing one or two geotextile layers onto the geomembrane layer in a continuous far infrared ray heating oven. The production process involves the addition of polymer and anti-aging materials, which enhance its performance in unconventional temperature environments.

The composite geomembrane liner offers high physical and mechanical properties, including tensile strength, tear resistance, and bursting strength. This makes it suitable for diverse civil engineering projects such as water conservancy, municipal administration, construction, transportation, subway, and tunnel applications.

The composite geomembrane liner provides a multifunctional solution by combining the advantages of geotextiles and geomembranes,. The geotextile layer enhances tensile strength, while the geomembrane layer ensures impermeability, effectively preventing leaks and moisture penetration.

The applications of composite geomembrane liners are extensive. In landfills, they act as a barrier to prevent the migration of contaminants into the surrounding soil and groundwater. Wastewater treatment facilities utilize these liners to contain and manage effluent, ensuring proper treatment and disposal. During road construction, composite geomembrane liners provide stability and prevent moisture ingress, enhancing the durability of road structures. In aquaculture, they create secure containment systems for fish or shrimp farming, preventing water contamination and facilitating proper management. Composite geomembrane liners find application in landscaping and agriculture. They offer erosion control, water retention, and protection against soil contamination, contributing to sustainable and environmentally friendly practices.

2. Specifications of Composite Geomembrane Liner

| Test Item | Test Properties | Unit | GSO4 | GSO5 | GSO6 | GSO7 | GSO8 |

|---|---|---|---|---|---|---|---|

| Weight | g/m2 | 400 | 500 | 600 | 700 | 800 | |

| Film Thickness | mm | 0.25-0.35 | 0.30-0.50 | ||||

| Mechanical Properties | Break Strength | kN/m | 5.0 | 7.5 | 10.0 | 12.0 | 14.0 |

| Break Elongation | % | 30-100 | 30-100 | 30-100 | 30-100 | 30-100 | |

| CBR Burst Strength | KN | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | |

| Tear Resistance | KN | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | |

| Peel Strength | N/cm | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 | |

| Hydrostatic Pressure | Film Thickness | mm | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 |

| One cloth one film | MPa | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | |

| Two cloth one film | MPa | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | |

3. What Are Features of Composite Geomembrane Liner?

composite geomembrane liners offer a range of features including the combined benefits of geotextiles and geomembranes, options for textured or smooth surfaces, enhanced durability, high tensile and tearing strength, chemical and UV resistance, reduced potential for delamination, simplified installation, OEM/ODM availability, and competitive factory pricing. These features make composite geomembrane liners suitable for diverse applications requiring impermeable barriers or containment systems.

3.1 Benefits of Geotextiles and Geomembranes

Composite geomembrane liners combine the advantages of geotextiles and geomembranes in a single product. This integration allows for enhanced performance and functionality, as the geotextile layer provides additional properties such as filtration, separation, reinforcement, and drainage, while the geomembrane layer ensures impermeability.

3.2 Textured or Smooth Surfaces

Composite geomembrane liners are available with options for textured or smooth surfaces. Textured surfaces provide increased friction coefficient, which improves stability and prevents slippage in slope and containment applications.

3.3 Enhanced Durability and High Friction Coefficient

The combination of geotextiles and geomembranes in composite geomembranes enhances durability and resistance to mechanical stresses. The geotextile layer helps distribute loads and protects against punctures or abrasions, thereby extending the overall lifespan of the liner system. Additionally, the high friction coefficient of composite geomembranes improves stability and reduces the risk of slippage.

3.4 High Tensile and Tearing Strength, Anti-Puncture

Composite geomembrane liners exhibit high tensile and tearing strength, making them resistant to ruptures and tears. They also provide excellent puncture resistance, ensuring reliable containment and preventing leakage.

3.5 Excellent Chemical and UV Resistance

Composite geomembrane liners offer exceptional resistance to various chemicals, including acids, alkalis, and organic solvents. They are also highly resistant to UV radiation, ensuring long-term performance and stability in outdoor environments.

3.6 Anti-Aging and Anticorrosion Properties

Composite geomembrane liners are designed with anti-aging and anticorrosion additives, which enhance their resistance to degradation over time. This prolongs their service life and maintains their performance in challenging conditions.

3.7 Reduced Potential for Delamination

The integration of geotextile and geomembrane layers in composite geomembranes minimizes the potential for delamination, ensuring the integrity and longevity of the liner system. This reduces the risk of layer separation or detachment, maintaining the liner’s effectiveness as a barrier.

3.8 Simplified Installation

Composite geomembrane liners simplify the installation process by eliminating the need for separate installation of geotextiles and geomembranes. This reduces labor requirements and installation time, resulting in cost savings and improved efficiency during installation.

3.9 OEM/ODM Availability

BPM provide OEM and ODM services, allowing for customization of composite geomembrane based on specific project requirements.

3.10 Competitive Factory Price

Composite geomembrane liners are typically offered at competitive factory prices, making them a cost-effective solution for various applications.

4. What Are Composite Geomembrane Liner Used For?

Composite geomembrane liner has the functions and advantages of both geotextiles and geomembranes, composite geomembrane is widely used for environmental protection, traffic facilities, roads construction, aquaculture, water resources protection, municipal projects and mining industry, etc al.

- Environmental protection. Landfills, sewage treatment plant, solid waste containment of industrial and hospital, etc.

- Traffic facilities. Road or airport foundation reinforcement, anti-seepage of subway and culvert, etc.

- Aquaculture. Anti-seepage of ditch, channel, reservoir, drinking water tank, pool, irrigation system and fish, shrimp farms, etc.

- Water resources protection. Anti-seepage leakage blockage and reinforcement of river, lake, reservoir, bank, anti-seepage of canal, side slope, etc.

- Municipal projects. Subway and underground engineering structures , anti-seepage of plantation roof and roof garden, lining of sewage pipe, etc.

- Mining industry. Anti-seepage of ash field, dissolving tanks, yard pile and tailings, etc.

5. Who Makes Composite Geomembrane?

BPM Geosynthetics is the manufacturer of composite geomembranes. We have their own 36,000 square meters geomembrane factory where they produce a variety of geomembrane products, including HDPE, LLDPE, textured, and composite geomembranes.

BPM composite geomembrane is available in two configurations: one geotextile and one geomembrane, and two geotextiles and one geomembrane. This allows for flexibility in selecting the appropriate composite geomembrane based on the specific requirements of the project.

With our dedicated factory and expertise in geomembrane production, BPM Geosynthetics is able to provide high-quality composite geomembranes that meet industry standards. Their range of products ensures that customers can find the right geomembrane solution for their applications, whether it is for environmental containment, civil engineering projects, or other specialized requirements.

BPM Geosynthetics has control over the geomembrane production process, ensuring consistent quality and timely delivery. Our commitment to providing reliable and durable geomembrane products has established them as a trusted manufacturer in the industry.

6. About BPM Geomembrane

BPM Geomembrane had provided many types of effective and states of the art geomembrane and other geosynthetics to over 36 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

BPM is not only manufacturing best quality geomembrane products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.