HDPE geomembrane specifications define the minimum requirements for the supply and installation of the HDPE geomembranes for the anti seepage lining project. HDPE geomembranes are available in various thicknesses, widths, and roll lengths to suit different project requirements. Geomembrane are also typically manufactured in large rolls and can be customized based on specific application needs.

In this article, let’s explore the HDPE geomembrane specifications in detail.

1 What Is A HDPE Geomembrane?

HDPE geomembrane is the top choice for lining projects due to its versatility and widespread usage. Resistant to a wide range of solvents, HDPE geomembrane liners are globally recognized and extensively employed. While slightly less flexible than LLDPE, HDPE geomembranes offer superior specific strength and resilience to higher temperatures. Their exceptional resistance to chemicals and ultraviolet exposure makes them an economically efficient solution for various applications such as canal, aquaculture, irrigation ponds and remediation liners, other liner applications include landfills, waste water treatment lagoons, oil and gas exploration, power plants, biogas projects, etc. All BPM geomembrane HDPE liner is in accordance with GRI GM13 standard.

2 What Are HDPE Geomembrane Specifications?

HDPE Geomembranes are synthetic liners or barriers used in various applications to contain or control the movement of fluids or gases. High-density polyethylene (HDPE) geomembrane liners are widely used in various applications such as landfill liners, mining and tailings containment, pond and reservoir liners, canal and irrigation systems, environmental protection barriers, and agricultural water storage.

The HDPE geomembrane specifications can vary depending on the specific project requirements, but there are some common specifications:

2.1 Material

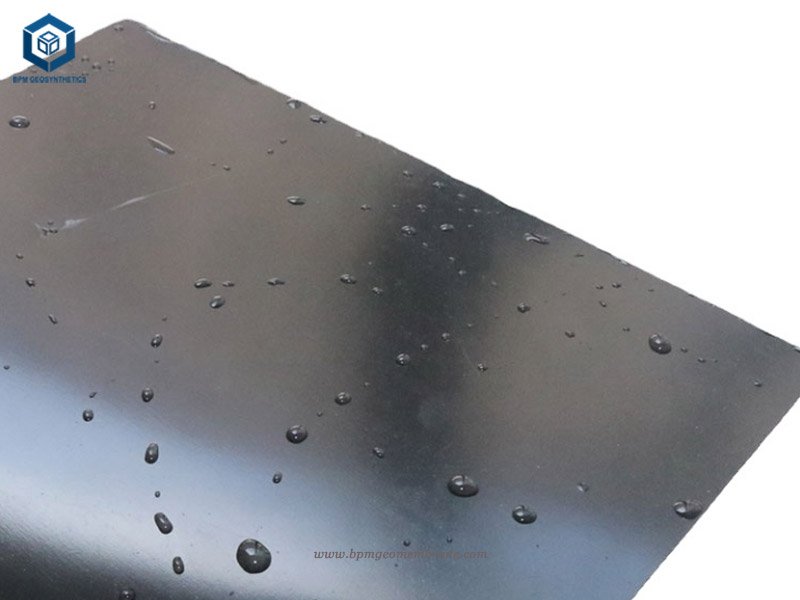

BPM brand smooth geomembrane HDPE liner is crafted from premium virgin high-density polyethylene (HDPE). It incorporates a carefully formulated blend, including specified quantities of carbon black, antioxidant, anti-aging agents, and UV-resistant components. This unique composition imparts outstanding UV radiation resistance to our geomembrane product, making it well-suited for applications in exposed conditions.

2.2 HDPE Liner Thickness

HDPE geomembrane is available in various thicknesses, typically ranging from 0.5 mm to 3.0 mm (20 mil to 120 mil). Mil and millimeter are units of HDPE geomembrane thickness measurement. Generally, 1 mil is equal to 0.0254 millimeters. So, to convert mils to millimeters, you can use these conversion factors:

- To convert inches to millimeters: inches × 25.4

- To convert millimeters to inches: millimeters ÷ 25.4

The commonly used HDPE liner thickness is 0.5mm, 1.0mm, 1.5mm, 2.0mm, and 3mm, converting to mil is 20mil, 40mi, 60mil, 80mil, and 120mil. The appropriate thickness depends on factors such as the application, project requirements, and site conditions.

2.3 Color Options

HDPE geomembrane has various colors. Black is a regular color, and it also can produce one side black, another side white, blue, green color, or both sides white, blue, green color, etc. Generally, colored geomembrane cost is higher than black geomembrane.

2.4 HDPE Liner Width

HDPE geomembrane liner typically comes in rolls with widths ranging from 1 meter to 10 meters (3 feet to 33 feet). The width can be customized based on the project requirements. Knowing the exact with of each HDPE geoemembrane liner roll, with thickness and other parameters, then you can choose best China HDPE liner roll for you specific project.

2.5 Textured vs Smooth Geomembrane

HDPE geomembranes are available in both smooth and textured surface finishes. Textured HDPE geomembrane feature a pattern of raised studs or dimples on one or both sides. The texture enhances frictional resistance, providing better interface friction between the liner and adjacent materials, which can be especially useful in slope and landfill applications. Smooth geomembrane HDPE Liner, on the other hand, offer advantages such as easier cleaning and reduced friction during installation. You understand the difference between textured and smooth geomembrane, you can make right decision for HDPE geomembrane projects.

3 What Are HDPE Geomembrane Features?

HDPE geomembrane is a thermoplastic polymer known for its excellent combination of properties, making it suitable for lining applications. Some key characteristics of HDPE geomembranes include:

3.1 Impermeability

HDPE geomembrane has very low permeability, meaning they effectively prevent the passage of liquids and gases. This property makes them ideal for applications requiring containment, such as landfills, ponds, reservoirs, and wastewater treatment facilities.

3.2 Tensile Strength

HDPE liners have high tensile strength to withstand stress and strains. The tensile strength is typically specified in both the machine direction (MD) and cross-machine direction (CMD). The values can vary but are commonly in the range of 3 kN/m to 80 kN/m (17 lb/in to 456 lb/in) in both directions.

3.3 Tear Resistance

HDPE geomembrane should have good tear resistance to prevent damage during installation and use. The tear resistance is typically specified in both the MD and CMD and can range from 25 N to 374 N (5.6 lb to 84 lb) in both directions.

3.4 Puncture Resistance

Puncture resistance is an important specification to consider, especially in applications where sharp objects or rocks may be present. HDPE liners generally have a puncture resistance ranging from 64 N to 960 N (14.5 lb to 215 lb).

3.5 Chemical Resistance

HDPE geomembranes exhibit excellent resistance to a wide range of chemical substances, including acids, alkalis, and various organic solvents. The specific chemical resistance properties should be evaluated based on the project requirements and chemical exposure.

3.6 Durability

HDPE geomembranes are highly durable and resistant to environmental stress cracking, UV radiation, and mechanical damage. They can withstand harsh weather conditions, temperature variations, and physical stresses associated with installation and use.

3.7 Flexibility

HDPE geomembranes have good flexibility, allowing them to conform to irregular surfaces and accommodate ground movements. This flexibility aids in the installation process and helps ensure proper containment.

3.8 Weldability

HDPE geomembranes can be easily joined together through thermal welding techniques. This enables the creation of large, continuous liner systems without the need for additional seams or connections, enhancing the overall integrity of the liner. Welding strength and integrity are important factors to consider. Weldability is the important consideration to ensure successful HDPE geomembrane installation.

3.9 Longevity

HDPE geomembranes have a long service life when installed and maintained properly. They can provide reliable containment for several decades, making them a cost-effective solution for long-term projects.

4 Conclusion

HDPE geomembrane is a commonly used geosynthetic material. There are other types of geomembranes available, such as PVC gemembrane. Understanding the difference between HDPE and PVC geomembrane liner can help you choose the preferred geomembrane liner. Other factors such as installation conditions, and budget constraints also should be considered.

You can select and install HDPE liner according to HDPE geomembrane specifications, industry standards, project-specific requirements, and the recommendations of geomembrane manufacturers or engineering professionals to ensure optimal performance and longevity.

BPM Geomembrane has four geomembrane production lines, all of which use high-quality imported raw materials. The HDPE Geomembrane Specifications including width, length, and all technical data can also be produced according to customer requirements. If you have any specific questions or would like more information about a particular aspect of HDPE geomembrane liners, feel free to ask!

Thank you for reading.