Textured and smooth geomembranes are the main geomembrane categories. The primary difference between the textured geomembrane and smooth geomembrane lies in their anti-seepage characteristics. Smooth geomembrane lacks an anti-slip feature because of its smooth surface. Whereas textured geomembrane, with their uneven surface, provides an anti-slip effect, it is widely used in slopes and similar environments. Therefore, when utilizing or designing anti-seepage projects, it is crucial to recognize and comprehend the distinctions between textured and smooth geomembranes.

BPM is the leading China geomembrane manufacturer and supplier. We have 13+ years industrial experiences on geomembrane fabrication and installation services. In this article, we will explore the similarities and differences between textured and smooth geomembrane in civil engineering applications.

1 What is A Textured Geomembrane

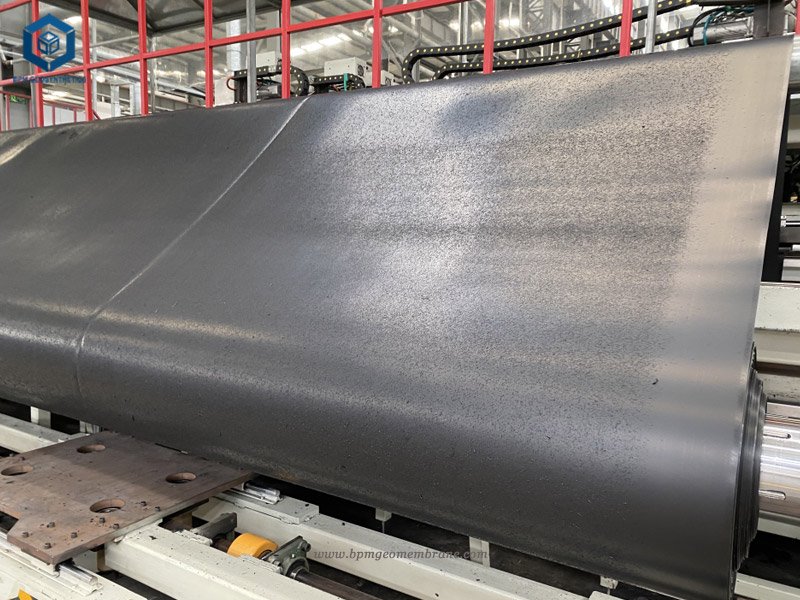

Textured geomembrane refers to a geomembrane with rough raised textures on the surface, which is divided into single texture surface and double texture surface. Compared with smooth geomembranes, the surface friction coefficient of textured geomembranes is larger and has anti-slip function. Textured HDPE geomembrame can be applied to slope anti-seepage and improve project stability.

2 What is A Smooth Geomembrane

Smooth geomembrane refers to a smooth geomembrane with smooth surface on both sides. It is more suitable for the anti seepage application for large flat surfaces and the short gentle slopes.

2 What is the Similarity of Textured And Smooth Geomembrane

2.1 Material Composition

Both textured and smooth geomembranes are typically constructed from high-density polyethylene (HDPE) or other polymer materials. What Raw Material is Used for Geomembrane by BPM?

Smooth HDPE geomembrane liner is made of premium virgin HDPE resin designed specifically for geomembrane production along with adequate carbon black, antioxidant, and stabilizers to have superior mechanical properties and outstanding long-term resistance to chemical, ozone, oxidation, environmental stress crack, and UV radiation. These advantages make BPM geomembrane the most suitable for those exposed or non-exposed applications.

HDPE smooth geomembrane production process: raw material preparation → production line preparation → extrusion preparation → automatic feeding → heating extrusion → blowing → circulating cooling → product molding → traction → rewinding → inspection → packaging and storage.

The production of textured geomembrane (single rough, double rough) is derived from the conventional manufacturing process of smooth geomembrane. Through modifications to the process equipment, the surface of the smooth impermeable membrane is deliberately roughened (via a spray roughening technique), enhancing the frictional properties of the geomembrane surface.

2.2 Seepage Prevention

The primary function of two types of geomembranes is to prevent seepage and control fluid migration. Whether the surface is smooth or textured, the geomembranes serve as barriers to the passage of liquids, contributing to effective containment.

BPM HDPE anti-seepage geomembrane has an anti-seepage effect that is unmatched by ordinary waterproof materials. HDPE geomembrane has high tensile resistance and mechanical properties. Its excellent elasticity and deformation ability make it very suitable for expansion or contraction bases. surface, which can effectively overcome the uneven settlement of the base surface. The water vapor permeability coefficient K<=1.0*10-13g.cm/c cm2.s.pa.

2.3 Environmental Resistance

Both textured and smooth geomembranes exhibit resistance to environmental factors such as UV radiation, chemical exposure, and temperature variations. This resistance enhances their longevity and performance in diverse settings.

BPM textured and smooth geomembrane has excellent chemical stability and is widely used in sewage treatment, chemical reaction tanks, and landfills. It is resistant to high and low temperatures, asphalt, oil and tar, and is resistant to corrosion by more than 80 strong acid and alkali chemical media such as acid, alkali and salt.

2.4 Geomembrane Installation Flexibility

Textured and smooth geomembranes offer best flexibility in geomembrane installation.

2.4.1 Smooth Geomembrane Installation

Before paving HDPE smooth geomembrane, measurement and positioning work is required. Measure and stake out the side lines on both sides of the paving. Then use the method of pulling wires to position on the side lines, calculate the area that needs to be paved, and calculate the paving area. Strict control and transfer of the sideline. The transfer method used at the construction site is manual lifting. The main method is to use steel pipes to penetrate the core and tie rope sleeves to the steel pipes exposed on both sides for lifting.

During the transfer process of smooth geomembrane HDPE liner, it is forbidden to tear the package to prevent the geomembrane from being damaged and paved.

When rolling, use a rope to lower it slowly, and do not roll it down directly. When paving the bottom of the warehouse horizontally, first connect one end to the adjacent block, fix it with sand bags, and then manually push the paving and welding.

Test welding. Before formal welding of the smooth geomembrane HDPE liner, in order to ensure that the welding quality meets the welding requirements, it is necessary to conduct a test welding of the geomembrane. After trial welding of the HDPE smooth geomembrane, the working conditions during the formal welding construction can be reasonably adjusted, and then the reasonable welding temperature, speed and pressure can be determined.

Trial welding completed. After the trial welding is completed and the sample quality is tested under satisfactory temperature conditions on that day, large-area welding construction can be carried out. If the test results do not meet the design requirements, try welding again until the test results meet the requirements. The welding parameters of the sample that meet the requirements are the primary basis for formal welding, and trial welding must also be carried out during kneading and fusion welding.

2.4.2 Textured Geomembrane Installation

The choice of single-rough surface textured geomembrane or double-rough surface geomembrane in slope anti-seepage construction is mainly determined by the specific construction environment. The textured geomembrane has high friction and should be in contact with the geotextile to prevent sliding. If geotextiles need to be laid on both upper and lower sides of the textured geomembrane, then double textured geomembranes should be selected. If geotextiles are laid on one side of the rough geomembrane, single rough geomembranes can be selected.

The rough surface of the textured geomembrane liner is also determined by the geotextile that needs to be in contact. If the geotextile is laid on the upper part of the single rough surface geomembrane, then the rough surface of the textured surface geomembrane should face upward. If the geotextile is laid on the upper part of the single-rough surface geomembrane, The lower part of the rough surface, then the rough surface of the single textured geomembrane should face downward. In daily construction, the rough surface of single-rough surface geomembrane is mostly facing downward.

At present, whether it is a single textured geomembrane or a double textured geomembrane, there are corresponding national standards and construction specifications. Therefore, when choosing a textured geomembrane, you should choose a geomembrane that meets the standards, and when laying the geomembrane, you should strictly follow the specifications. Only in this way can the quality of the entire anti-seepage construction be guaranteed.

BPM geomembrane has good welding effect – HDPE anti-seepage membrane is welded by a special welding machine, and the welding effect is very good. The strength of the weld is greater than the strength of the base material and is easy to construct.

BPM HDPE anti-seepage membrane has high flexibility. It has various specifications and laying forms to meet the anti-seepage requirements of different projects. It adopts hot-melt welding, the weld strength is high, and the construction is convenient, fast and healthy.

2.4.3 Customization Options

Geomembrane Manufacturers often offer customization options for both textured and smooth geomembranes. This includes variations in thickness, width, and length to meet specific project demands.

BPM is not only manufacturing best quality geomembrane products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available.

3. What is the Difference Between Textured and Smooth Geomembrane

3.1 Different Surface Texture

The most apparent difference is the surface texture. Textured geomembrane has one or two sided rough surfaces. While smooth geomembrane has smooth surfaces on both sides.

3.2 Geomembrane Manufacturing Process

The manufacturing process for textured geomembranes involves creating a surface with irregularities or patterns, while smooth geomembranes have a flat and consistent surface. This process difference influences their physical properties.

3.3 Anti-Slip Properties of Textured vs Smooth Geomembrane

Textured geomembranes are designed with an uneven surface that provides excellent anti-slip properties. This unique feature makes them highly suitable for applications in sloped terrains or areas where traction is of utmost importance. In contrast, smooth geomembranes lack this anti-slip effect, making them less ideal for such scenarios.

3.4 Applications of Textured and Smooth Geomembrane

Smooth geomembranes are commonly used in applications where an anti-slip surface is not a primary requirement, such as containment ponds, landfills, or water reservoirs. Textured geomembranes, with their anti-slip feature, find applications in slopes, liners for landfill caps, and other environments where traction is essential.

3.5 Different Price

HDPE smooth geomembrane (single rough, double rough) is based on the traditional production of smooth geomembrane, and the process equipment is modified, so that the surface of the produced smooth anti-seepage membrane is roughened (blasted rough). Therefore, the price of rough geomembrane is slightly more expensive than that of smooth geomembrane.

4.Conclusion

Both the textured and smooth geomembranes are the cost effective geosynthetic material for environmental protection, water and waste containment, and seepage prevention projects. Textured geomembrane is designed with one or two rough surface. It is preferable for slope application. It also has the higher price than smooth geomembrane.

BPM can offer you with the most suitable geomembane products based on your site environment and project requirements. By carefully considering factors such as traction needs, slope stability, and project constraints, you can make informed decisions that ensure optimal performance and longevity of the geomembrane system.

Any questions or inquiries on how to select geomembrane products. please contact us.

Thank you for reading.