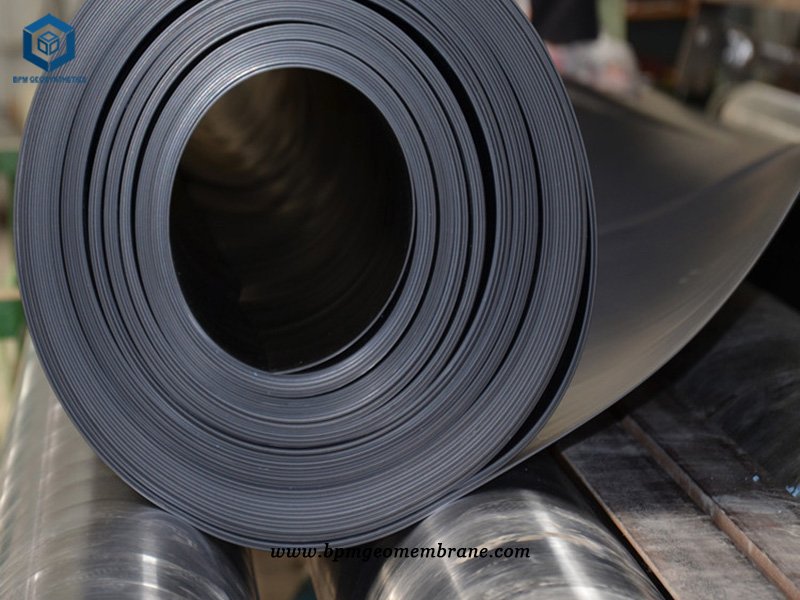

HDPE geomembrane liner, including 2mm HDPE liner or 80 mil HDPE Liner, is the most commonly used lowest permeable synthetic materials for anti seepage lining applications such as landfills, water containment and waste containment. The main feature of BPM HDPE geomembrane liner is that it is chemically stable, and landfill leachate will not affect is chemical properties. If there are slopes, textured geomembrane liners are the best choice. The low permeability of BPM HDPE liner can ensure that groundwater and rainwater infiltration fluid will not penetrate into the lining, and methane gas will not overflow the drainage system. The stable UV resistance and the carbon black in the raw materials enhances UV resistance.

1. What is 2mm HDPE liner?

A 2mm HDPE liner is a geomembrane made of high-density polyethylene with a thickness of 2 millimeters. HDPE is a durable and chemically resistant material commonly used for containment applications. The liner is designed to provide a reliable barrier against the seepage of liquids, gases, or contaminants.

The 2mm thickness of the HDPE liner offers a balance between flexibility and strength. It allows for easy installation and conformability to the underlying surface while still providing sufficient resistance to punctures and tears.

HDPE liners are widely used in various industries, including landfill projects, mining operations, agricultural applications, and pond or reservoir lining. They are chosen for their excellent chemical resistance, UV stability, and long-term durability. The 2mm HDPE liner is suitable for projects that require a moderately thick liner to ensure effective containment and environmental protection.

Overall, the 2mm HDPE liner is a versatile and reliable solution for applications that demand impermeability, durability, and resistance to chemicals and environmental factors.

2 Why Choose 2mm HDPE Liner for Landfill Projects?

At present, most landfills in the United States use two-layer HDPE geomembrane for seepage prevention, and the design standards for toxic and hazardous waste landfills are higher. In the early 1990s, BPM began to use HDPE geomembrane liner especially 2mm HDPE liner as the main anti-seepage material for landfills. HDPE geomembrane liner is not only used as the main material for the anti-seepage system of the bottom and side walls of the landfill, but also widely used as the main anti-seepage layer of the landfill cover system and the anti-seepage lining of the leachate adjustment tank. Therefore, the application of HDPE geomembrane liner anti-seepage technology in domestic landfills has very broad development prospects. The project was located in Thailand, The customer chose 2mm HDPE Liner as the landfill cover system.

Preventing landfill gas and leachate from polluting the environment is the most important consideration in a landfill project. Careful consideration of landfill gas and leachate needs to run through the entire life cycle of the landfill from design, construction, operation to closure and post-closure management. The anti-seepage system at the bottom of the reservoir is an important facility to prevent landfill gas and leachate pollution and prevent groundwater and surface water from entering the landfill.

The horizontal seepage control system of a landfill usually includes a filter layer, a drainage layer, a protective layer and an anti-seepage layer from top to bottom. The impermeable layer is the most important layer in the horizontal impermeable system. Its function is to lay low-permeability materials in the landfill to prevent the leachate from migrating to the environment outside the landfill; the anti-seepage layer can also block surface water and groundwater from entering the landfill. The horizontal anti-seepage 2 mm HDPE liner system can be divided into single liner system, composite liner system, double liner system and multi-liner system. The impermeable layer is made of impermeable material with less water permeability. The materials suitable for the anti-seepage system of the landfill include inorganic natural anti-seepage materials, natural organic composite anti-seepage materials and synthetic organic materials.

3. Solution of 80 mil HDPE Liner for Landfill project

For the landfill project in Thailand, our solution is an 2 mm HDPE liner or 80 mil HDPE (High-Density Polyethylene) liner. This recommendation is based on our previous experience and expertise in the field.

The HDPE geomembrane liner offers several advantages for this application. Its chemical stability ensures that landfill leachate is effectively contained, preventing it from seeping into the liner and protecting groundwater and rainwater leachate from contamination. Additionally, the HDPE liner has stable UV resistance, and the inclusion of carbon black further enhances its ability to resist ultraviolet rays. This solves the problem of easy decomposition when exposed to sunlight.

To provide assurance of the quality and performance of the 2 mm HDPE liner, we have sent detailed indicators and test reports to the customer. Their satisfaction with the results of these tests further confirmed the suitability of our recommendation. We also provided the customer with samples of the HDPE liner for their own testing, which resulted in their high satisfaction with the product.

After quoting the customer, we were able to reach an agreement for the order, and our team continued to provide professional advice and guidance throughout the process. We are committed to ensuring that our customer’s landfill project in Thailand is successful, and we are dedicated to delivering a high-quality solution tailored to their specific needs.

4. Specification of 2mm HDPE Liner for Landfill project in Thailand

For the landfill project in Thailand, the specifications of the 2mm HDPE liner are as follows:

- HDPE Geomembrane Liner thickness: 2mm

- Total Quantity: 120,000 square meters

- Each roll Size: 7m*100m

The 2mm thickness of the HDPE liner ensures a strong and durable barrier against leachate seepage in the landfill. With a total quantity of 120,000 square meters, an ample amount of liner is available to cover the required area.

Each roll size measures 7 meters in width and 100 meters in length, providing convenient installation and sufficient coverage for the landfill project.

These specifications demonstrate that the chosen 2mm HDPE liner meets the necessary requirements for the landfill application in Thailand. The liner’s thickness, total quantity, and roll size are designed to effectively contain landfill leachate and ensure the long-term integrity and functionality of the project.

5. The Advantages of 2 mm HDPE Liner for Landfills

5.1 Excellent Performance

BPM company specializes in the production of high-quality waterproof HDPE geomembrane liner with high chemical stability. The chemical properties of this geosynthetic material are heat and cold resistance. The high-quality waterproof high-density polyethylene lining exerts its excellent performance in the production process, so the produced anti-seepage high-density polyethylene lining also has the characteristics of raw materials.

5.2 High Tensile Strength

BPM HDPE geomembrane liner is heat-resistant, cold-resistant and waterproof. In addition to the anti-seepage function, BPM high-quality waterproof HDPE geomembrane liner is also very flexible, so the high-quality waterproof HDPE geomembrane liner also has strong resistance to environmental pressure, that is, the high-quality waterproof HDPE geomembrane liner has high Tensile Strength.

5.3 Long Service Life

The production process of BPM high-quality waterproof HDPE geomembrane liner is strictly controlled. Due to the corrosion resistance of the materials used in the production, the BPM high-quality waterproof HDPE geomembrane liner is not afraid of acid and alkali substances, preventing its long-term corrosion and increasing the service life.

6. Construction Technology of 2 mm Geomembrane Liner for Landfill Project

6.1 Construction preparations for waste landfills

After the bottom of the landfill is leveled, according to the design requirements, the underground water collection trench is manually excavated, the remaining soil is transported to the surrounding area of the reservoir bottom, the impermeable material is laid from the bottom up, the gravel groundwater diversion layer membrane material and the upper and lower geotechnical materials are laid cloth. After the inspection, the prepared pebbles are laid by machinery and manually. The specific operation is as follows: First, lay the plastic film and upper geotextile of the reservoir dam. After the plastic film and the upper geotextile are laid and accepted, an excavator is arranged at the bottom and crest of the dam to transport the pebble diversion layer to the slope of the reservoir dam and level it manually. In order to ensure the laying quality, the membrane material laying and the diversion layer should be carried out equally, and the construction should be divided into regions. The construction sequence of landfill leveling is to clear the slope first, then level the bottom of the reservoir; the principle of slope leveling is to save earthwork. When leveling, the topsoil in the bottom of the reservoir is first removed and stacked in the overburden preparation site as daily covering soil.

6.2 Construction Process

Reservoir bottom plane compaction—30cm thick pebble groundwater diversion layer—laying filament geotextile (200g/m2)—laying 30cm thick clay layer, laying 4800G/m2 of bentonite cushion, 2mm HDPE liner, Seam welding-laying filament geotextile (600g/m2), 2cm thick medium and coarse sand layer-filament geotextile (200g/m2), 30cm thick pebble leachate diversion layer-filament geotextile Cloth 200g/m2), then primary garbage.

6.3 Quality inspection of 2 mm Geomembrane Liner

The anti-seepage membrane and geotextile used in the project are two-cloth one membrane and one-cloth one membrane needle-punched anti-seepage membrane and geotextile. Entrust a laboratory to test the technical indicators of the product before use, and all indicators meet the standard requirements and design requirements. The impervious geomembrane and geotextile have certain blast resistance and puncture resistance capabilities, but in the process of landfilling garbage, the gravel and roots under the membrane are often destroyed. In the anti-seepage construction of the landfill, the earthwork is excavated to the clay layer, the slope is excavated according to the design size, the slope is backfilled and compacted, and the level is watered and compacted, so that the dry bulk density of the compacted filler is not less than 1.65t/m3. Remove hard and sharp objects such as rocks and tree roots on the surface, and spray chemicals such as herbicides. The slope surface after completion should be smooth, dense and even to prevent piercing the impermeable membrane and geotextile. After meeting the design flatness requirements, the supervision engineer will accept it to provide a working surface for laying the anti-seepage membrane and geotextile.

6.4 2mm HDPE Liner Insllation Method

The installation method for the 2mm HDPE liner is as follows:

1. Prepare the site: Ensure that the bottom of the reservoir or slope is properly prepared and free from any sharp objects or debris that could damage the liner.

2. Splicing and welding: On a flat ground, splice and weld the sections of the impervious HDPE geomembrane and geotextile to create a continuous sheet with a width of 20m. This process ensures a secure and watertight connection.

3. Laying on the slope: Start laying the HDPE liner and geotextile on the slope surface perpendicular to the axis of the dam, from top to bottom. The liner should be carefully spread along the slope, ensuring it is aligned and free from wrinkles or protrusions.

4. Connection at the foot of the slope: Connect the groove at the foot of the slope with the geomembrane at the bottom of the reservoir on the top of the embankment. This connection ensures a continuous and sealed layer for effective containment.

5. Paving in the reservoir: After the acceptance of the excavation at the bottom of the reservoir, slowly pave the HDPE liner and geotextile in the reservoir from the top of the tooth groove towards the foot of the embankment along the direction perpendicular to the axis of the embankment foot.

6. Wave-shaped laying: To facilitate splicing and prevent stress concentration, the HDPE liner and geotextile should be laid in a wave shape, ensuring a margin of about 1.5%. This wave-like installation allows for some flexibility during settlement or movement of the underlying soil.

7. Leveling and smoothness: After the HDPE liner and geotextile are paved, they should be leveled and any excess material should be pulled out in a timely manner. Ensure that the liner and geotextile are consistent with the slope surface, without any protrusions or wrinkles.

8. Safety precautions: During the installation, construction personnel should wear flat-bottomed cloth shoes or soft rubber shoes to prevent damage to the liner. Spiked shoes should be avoided to prevent puncturing or tearing the geomembrane.

It is important to carry out the installation work in dry and warm weather conditions to ensure proper adhesion and alignment of the liner. Following these installation guidelines will help ensure a successful installation of the 2mm HDPE liner for effective containment and seepage prevention.

7. Summary

BPM HDPE geomembrane liner uses high quality raw materials with advanced processing technology and equipment, so it has the highest quality and the longest service life. The HDPE geomembrane liner produced by BPM has the best impermeability, excellent chemical resistance, excellent resistance to environmental stress cracking, excellent puncture resistance, excellent UV resistance, and stable low temperature resistance to embrittlement Performance and high cost performance. It is widely used in canals, aquaculture, irrigation ponds and repair liners. Other liner applications include landfills, wastewater treatment lagoons, oil and gas exploration, power plants, etc.

About BPM Geomembrane

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries.

BPM Geomembrane is not only manufacturing best quality geosynthetic products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us.