In today’s industrial world, choosing the right containment solution is critical for ensuring efficiency, safety, and environmental protection. One of the most reliable and popular options is the HDPE tank liner. The HDPE tank liner, made from high-density polyethylene, has become a go-to solution for lining tanks and preventing leaks, thanks to its robustness and chemical resistance. High-Density Polyethylene (HDPE) tank liners are widely used across industries such as agriculture, oil and gas, water treatment, and chemical storage due to their excellent properties. This article highlights the top ten benefits of HDPE tank liners for industrial applications, helping businesses understand why they are a smart investment.

1. What Is an HDPE Tank Liner?

An HDPE tank liner is a protective barrier crafted from high-density polyethylene (HDPE), a durable thermoplastic polymer designed to line tanks and containment structures. With a thickness typically ranging from 20 mil (0.5mm) to 120 mil (3.0mm)—80 mil (2.0mm) being common for industrial tanks—the HDPE tank liner boasts a density of approximately 0.94 g/cm³, offering strength and flexibility. Manufactured via extrusion processes in a geomembrane factory like BPM Geosynthetics, it features specifications such as tensile strength up to 53 kN/m (for 2.0mm) and puncture resistance of 640 N, per industry standards like GRI-GM13.

The HDPE tank liner is engineered to resist environmental factors—chemicals, UV exposure, and physical stress—making it a reliable choice for protecting tanks from leakage and degradation. HDPE liner manufacturers enhance it with additives like carbon black (2–3%) for UV stability, ensuring it withstands prolonged industrial use. Available in smooth or textured forms, the HDPE tank liner is a staple in applications requiring secure, long-term containment.

2. What Are Functions of HDPE Tank Liners?

The HDPE tank liner serves critical purposes in industrial settings, leveraging its robust properties:

2.1 Leak Prevention

The primary function of the HDPE tank liner is to prevent leaks, with impermeability ratings often exceeding 10,000mm. Produced by HDPE liner manufacturers, it ensures liquids—whether water, chemicals, or oil—stay contained within tanks.

2.2 Corrosion Protection

In chemical storage or oil and gas tanks, the HDPE tank liner shields metal or concrete surfaces from corrosive substances, extending tank lifespan—a key role refined by a geomembrane factory.

2.3 Environmental Safety

By containing hazardous materials, the HDPE tank liner prevents spills that could harm ecosystems or violate regulations—a vital function emphasized by HDPE liner manufacturers.

2.4 Structural Integrity

With tear resistance up to 249 N, the HDPE tank liner supports tank stability under pressure or weight, a practical benefit from geomembrane factory production.

3. 10 Benefits of HDPE Tank Liner for Industrial Applications

3.1 Benefits of HDPE Tank Liner – Superior Chemical Resistance

One of the most significant advantages of HDPE tank liners is their outstanding chemical resistance. HDPE is known for its dense molecular structure, which imparts resistance to a wide array of chemicals, including acids, bases, and solvents. This characteristic makes HDPE liners ideal for industries such as chemical processing, mining, and wastewater treatment, where exposure to corrosive substances is common. By deploying HDPE tank liners, businesses can prevent chemical degradation and ensure the longevity of their containment systems.

3.2 Benefits of HDPE Tank Liner – Exceptional Durability and Longevity

HDPE tank liners are renowned for their durability and long service life. The material’s high tensile strength and flexibility enable it to withstand mechanical stresses, punctures, and impacts. Additionally, HDPE’s resistance to environmental factors such as UV radiation and temperature fluctuations contributes to its extended lifespan. This durability ensures that HDPE liners maintain their structural integrity over time, reducing the frequency of repairs or replacements.

3.3 Benefits of HDPE Tank Liner – Cost-Effectiveness

While the initial investment in HDPE tank liners may be higher compared to some alternative materials, their long-term cost-effectiveness is noteworthy. The extended lifespan and minimal maintenance requirements of HDPE liners translate to reduced operational costs over time. Moreover, their ability to prevent leaks and environmental contamination can help businesses avoid costly fines and remediation expenses, further enhancing their economic appeal.

3.4 Benefits of HDPE Tank Liner – Ease of Installation and Maintenance

HDPE tank liners offer advantages in both installation and maintenance. The material’s flexibility allows for prefabrication into custom sizes and shapes, facilitating straightforward installation even in complex containment systems. Additionally, HDPE liners can be welded on-site, ensuring seamless and secure joints. Maintenance is typically minimal, involving regular inspections and occasional cleaning, which helps maintain the liner’s performance without significant downtime.

3.5 Benefits of HDPE Tank Liner – Environmental Protection

Implementing HDPE tank liners plays a crucial role in environmental conservation. Their impermeability prevents the leakage of hazardous substances into the surrounding soil and groundwater, mitigating the risk of environmental contamination. This protective feature is essential for industries dealing with pollutants, as it helps maintain ecological balance and ensures compliance with environmental regulations.

3.6 Benefits of HDPE Tank Liner – Versatility in Applications

The adaptability of HDPE tank liners makes them suitable for a wide range of industrial applications. They are commonly used in:

- Chemical Storage Tanks: Providing a resistant barrier against corrosive chemicals.

- Water and Wastewater Treatment: Ensuring containment of potable water and preventing seepage of contaminants.

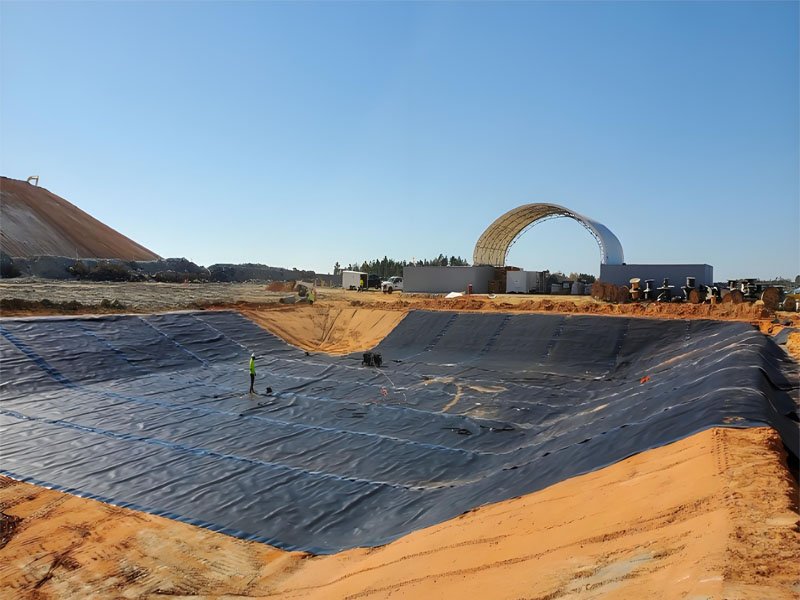

- Mining Operations: Lining tailings ponds and heap leach pads to prevent environmental contamination.

- Agricultural Ponds: Serving as liners for irrigation and livestock watering systems.

This versatility underscores the material’s suitability across diverse sectors.

3.7 UV and Weather Resistance

HDPE tank liners exhibit excellent resistance to ultraviolet (UV) radiation and adverse weather conditions. This property is particularly beneficial for outdoor applications, where exposure to sunlight and varying weather patterns is inevitable. The UV stability of HDPE liners ensures they do not degrade or lose functionality over time, maintaining their protective qualities without the need for additional coverings.

3.8 Customization and Flexibility

HDPE tank liners can be tailored to meet specific project requirements. They are available in various thicknesses, typically ranging from 40 mil (1.0 mm) to 80 mil (2.0 mm), allowing selection based on the application’s demands. This customization ensures optimal performance, as the liner’s thickness can be matched to the mechanical and chemical stresses it will encounter.

3.9 High Puncture and Tear Resistance

The robust nature of HDPE imparts high puncture and tear resistance to the liners. This characteristic is vital in industrial settings where the liner may be subjected to mechanical stresses during installation or operation. The material’s toughness ensures that it can withstand such challenges without compromising its integrity, thereby maintaining a secure containment system.

3.10 Compliance with Regulatory Standards

Utilizing HDPE tank liners aids industries in adhering to stringent regulatory standards related to environmental protection and safety. The liners’ effectiveness in preventing leaks and contamination aligns with compliance requirements, thereby reducing the risk of legal liabilities and enhancing the company’s reputation for responsible operations.

4. Conclusion

The integration of HDPE tank liners into industrial applications offers a multitude of benefits, from chemical resistance and durability to environmental protection and regulatory compliance. These advantages make HDPE liners a prudent choice for industries seeking reliable and cost-effective containment solutions. By opting for HDPE tank liners, businesses can ensure the safety, efficiency, and sustainability of their operations, thereby contributing positively to both their bottom line and the environment.

For more detailed information on HDPE tank liners, including specifications and application guidance, consulting with reputable manufacturers and suppliers is recommended. This approach ensures that the selected liner meets the specific needs of the application, thereby maximizing its benefits.